The Speed Paradox: Deconstructing the Maximum Velocity of a Forklift

The question "What is the maximum speed of a forklift?" does not have a single, universal answer. While a powered industrial truck, commonly known as a forklift, is a robust piece of machinery capable of high torque, its maximum design speed is almost always an order of magnitude higher than its maximum safe operational speed. The technical capabilities of the vehicle are constantly subordinated to the stringent demands of workplace safety, material stability, and regulatory compliance.

This technical article will deconstruct the concept of forklift speed, exploring the theoretical maximum speeds of different forklift classes, the fundamental physical and engineering principles that govern safe operation, and the critical role of occupational safety regulations in setting site-specific speed limits.

I. Maximum Design Speed: The Engine's Potential

The maximum speed a forklift is engineered to reach, often referred to as its "design speed" or "unloaded top speed," is primarily determined by its power source and drive train configuration.

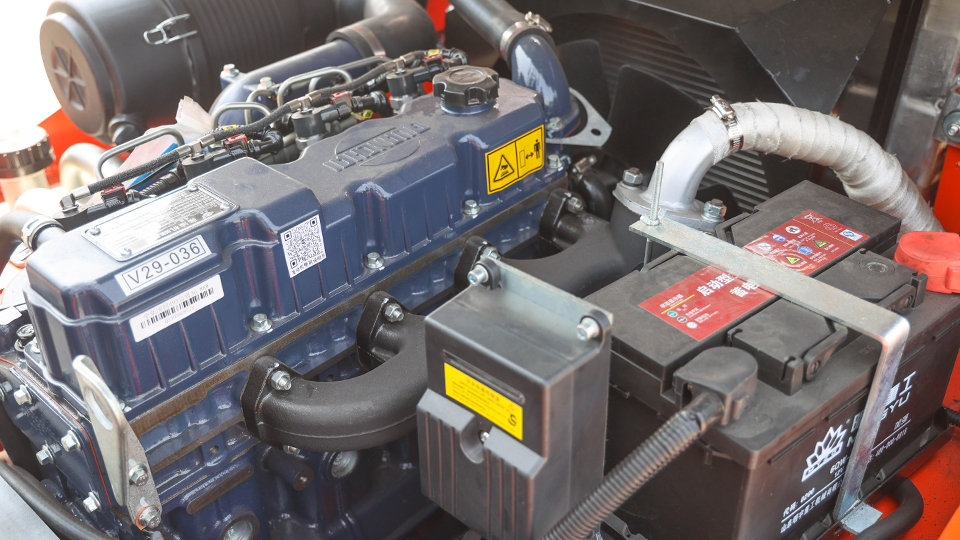

A. Internal Combustion (IC) Forklifts (Diesel, LPG, Gasoline)

Internal Combustion (IC) forklifts, which utilize powerful engines and pneumatic tires, are typically designed for outdoor, long-haul, and heavy-duty applications. Their power systems are geared to achieve higher absolute top speeds than their electric counterparts.

Design Range: Many IC counterbalanced lift trucks are technically capable of speeds ranging from 10 to over 20 miles per hour (16 to over 32 kilometers per hour) when running unloaded in an open-air environment.

Engineering Advantage: The IC engine provides high torque and the potential for greater acceleration over long distances, which is advantageous on large construction sites or container yards. Their traditional mechanical drive systems allow for higher maximum wheel RPM before mechanical or electronic limiting occurs.

B. Electric Forklifts (Battery-Powered)

Electric forklifts, including both standard counterbalanced and specialized warehouse trucks like reach trucks or pallet jacks, are optimized for precise control, maneuverability, and indoor use. Their top speed is often electronically governed to prioritize safety and battery efficiency.

Design Range: The technical maximum speed for most electric counterbalanced forklifts is generally lower than IC models, typically ranging from 6 to 10 miles per hour (10 to 16 kilometers per hour). Specialized, narrow-aisle electric trucks (like reach trucks) may have even lower programmed maximums, as stability is paramount in high-rack environments.

Engineering Focus: The electric motor system allows for extremely fine-grained speed control and smooth acceleration. Modern electric control systems (Electronic Control Modules or ECMs) often allow fleet managers to program a speed limit directly into the truck’s operating parameters, overriding the mechanical top speed.

C. Specialized Forklifts

The diversity of the "forklift" family means speed varies drastically across classes:

Forklift Class Typical Environment Unloaded Design Speed (Approx.) Speed Priority

Class V (IC Counterbalanced) Outdoors, Yards, Construction 10−20+ mph (16−32+ km/h) Power, Distance Travel

Class IV/I (Electric Counterbalanced) Indoors, Warehouses 6−10 mph (10−16 km/h) Control, Maneuverability

Class II (Narrow Aisle/Reach Truck) High-Rack Warehouses 4−7 mph (6−11 km/h) Stability, Precision Lifting

Class III (Electric Hand/Pallet Truck) Loading Docks, Short Hauls 3−5 mph (5−8 km/h) Control, Pedestrian Safety

导出到 Google 表格

In summary, while a powerful, unloaded IC forklift may technically be capable of speeds up to and exceeding 20 mph in a controlled environment, these maximums are rarely, if ever, relevant to real-world operation.

II. The Reign of Safe Operating Speed: Physics and Stability

The fundamental reason a forklift is almost always operated at a speed far below its maximum design capacity is the inherent instability of the machine and the critical role of the stability triangle.

A. The Stability Triangle and Center of Gravity

Unlike an automobile, a forklift's stability is not based on a four-point rectangular stance but on a three-point triangular configuration known as the stability triangle. This imaginary triangle is formed by the two front wheels and the midpoint of the rear axle (or a single central pivot point for three-wheel models).

The Center of Gravity (CoG) of the truck and its load must remain within this triangle for the vehicle to remain stable and avoid a tip-over. As a forklift accelerates, decelerates, or—most critically—turns, the momentum generated shifts the effective CoG.

B. Stopping Distance and Momentum

The immense weight of a forklift, combined with a potentially heavy load, creates significant kinetic energy that is difficult to dissipate, leading to long stopping distances. A standard counterbalanced forklift can weigh between 3,000 and 20,000 pounds.

The braking system must convert this kinetic energy into heat through friction. The distance required to stop (d) is directly proportional to the kinetic energy and inversely proportional to the stopping force (F):

As a practical example:

A forklift traveling at 4 mph may require approximately 17 feet to stop.

The same forklift traveling at 8 mph can require over 42 feet to come to a complete stop, illustrating the exponential increase in stopping distance with speed.

This physical reality means that in an environment with pedestrians, corners, or cross-aisles, the speed must be limited to ensure the operator can stop safely and avoid a collision, a principle enforced by regulatory bodies.

III. Regulatory and Industry Standards for Operational Speed

No matter the machine’s technical capability, the safe, legal operational speed of a forklift is not dictated by the manufacturer's top gear but by the worksite-specific rules, which are guided by national and international safety standards.

A. OSHA and the Principle of Safe Stop

The U.S. Occupational Safety and Health Administration (OSHA) does not mandate a specific numerical speed limit for powered industrial trucks. Instead, it relies on a performance-based standard that places the responsibility on the employer:

29 CFR 1910.178(n)(8): "The truck shall be operated at a speed that will permit it to be brought to a stop in a safe manner under all travel conditions."

This regulation effectively means the maximum safe speed is a dynamic variable that changes with conditions such as:

Load: Speed must be reduced with heavier, wider, or taller loads.

Surface: Speed must be reduced on wet, slippery, or uneven floors.

Visibility: Speed must be reduced when approaching intersections or blind spots.

Pedestrians: Speed must be low enough to avoid striking any person.

B. Industry Recommendations: A Practical Consensus

While OSHA provides the legal framework, industry bodies offer practical numerical guidelines that reflect the safest operating speeds in real-world scenarios:

Environment Industry Recommended Speed (MHEDA) Industry Recommended Speed (km/h)Primary Safety Concern

General Warehouse Travel 5-8 mph 8-13 km/h Collisions with racks, equipment, or other vehicles

Areas with Pedestrians/Blind Spots 2-3 mph 3-5 km/h Preventing struck-by injuries and fatalities

These recommended speeds are the practical maximums enforced in the vast majority of operational environments worldwide. The typical set speed limit in a warehouse is often 5 mph, or even slower in congested zones.

C. Engineering Controls for Speed Management

Modern material handling fleets utilize technology to enforce these operational limits, overriding the driver's throttle command.

Electronic Speed Limiters/Governors: These are the most common form of control, programmed through the ECM (Electronic Control Module) on electric trucks or via a physical/electronic governor on IC engines. They electronically cap the maximum forward travel speed, ensuring the vehicle cannot physically exceed the site-specific limit, even if the pedal is fully depressed.

Proximity/Zone Control: Advanced systems use RFID, GPS, or ultra-wideband (UWB) technology to create variable speed zones. For instance, the system automatically reduces the forklift's maximum speed from 8 mph to 3 mph the moment it crosses an invisible boundary into a pedestrian walkway or high-density area.

Load-Sensing Limits: Some sophisticated systems link the speed limiter to the hydraulic load sensor. If the load is at a dangerously high elevation or exceeds a certain percentage of the rated capacity, the maximum allowed travel speed is automatically reduced to prevent a tip-over.

Conclusion: Safety Over Velocity

The maximum speed of a forklift is a figure dominated by safety constraints, not engine power. While a high-performance IC model may possess the technical capability to reach 20 mph, a responsible fleet manager or operator will never permit it to do so in an operational setting.

The definitive answer is that the maximum safe operating speed of a forklift rarely exceeds 8 mph in open areas and is frequently limited to 3−5 mph in indoor or congested pedestrian zones. This low speed is a non-negotiable engineering compromise, necessitated by the fundamental physics of momentum, stability, and the catastrophic risk of a high-speed collision or tip-over with a heavy piece of equipment. In the world of material handling, safety is the ultimate speed limiter.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China