The Geometry of Maneuverability: Calculating and Understanding a Forklift's Turning Radius

Introduction

The operational efficiency and safety of a material handling facility hinge on the proper selection and utilization of equipment. Among the most critical specifications for a forklift—whether electric counterbalance, internal combustion (IC) pneumatic tire, or a narrow-aisle reach truck—is its turning radius. Far from being a simple, fixed measurement, the turning radius is a complex geometric and engineering parameter that dictates the minimum required aisle width (MRAW), directly impacting warehouse layout, racking density, and the overall cost per pallet stored.

This article delves into the technical definition, the key components that govern the measurement, the mathematical methods for calculation, and the practical implications across various classes of industrial trucks. Understanding the turning radius is not just about moving a machine; it's about optimizing the choreography of the entire logistical operation.

I. Defining the Turning Radius: The Geometric FoundationIn general vehicle dynamics, the turning radius is the radius of the circular path traced by a vehicle's outermost point when executing its tightest possible turn. For a forklift, however, the terminology is often split into two more practical measurements defined by the Industrial Truck Association (ITA) and common engineering practice:

This is the radius of the circle traced by the outermost point of the forklift’s chassis during its tightest turn. This measurement is crucial for determining clearance when operating near walls, columns, or other equipment.

Minimum Aisle Width (MAW) / Minimum Required Aisle Width (MRAW): This is the ultimate practical dimension. It is the minimum straight-line distance required between two rows of racking or obstacles to allow the forklift to pick up or place a standard-sized load (typically a 48-inch pallet) and execute a 90-degree turn into the aisle. The MRAW is the true measure of a forklift’s utility in a defined space.

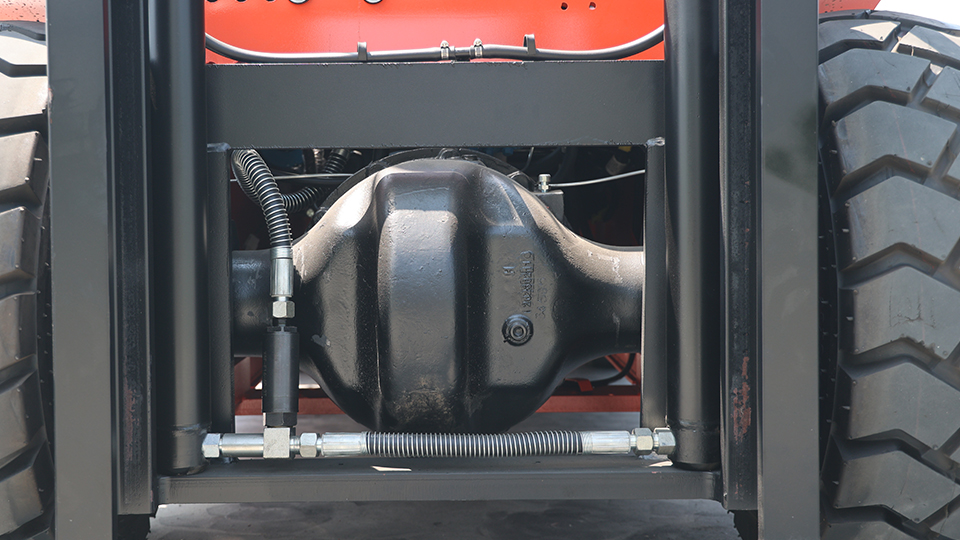

The key to a forklift’s tight maneuverability is the steering mechanism. Unlike a typical automobile that steers with the front wheels, most counterbalance and standard industrial forklifts steer with the rear wheels. This counter-intuitive design allows the truck to pivot around its front axle, enabling a smaller turning circle and greater agility in constricted spaces.

II. The Essential Components Governing the Radius Three primary dimensional parameters, specific to the forklift's design, form the inputs for the turning radius calculation:

A. Load Center Distance to Rear Axle Center (L r )

This is the horizontal distance from the center of the front axle to the center of the rear (steering) axle. Known as the wheelbase, it is the dominant factor in both stability and turning radius. A longer wheelbase generally provides greater longitudinal stability but requires a larger turning radius.

B. Front Overhang or 'Load Face to Centerline of Front Axle' (D c)

This measurement is the horizontal distance from the vertical face of the load carriage (the uprights) to the center of the front axle. This dimension directly affects the amount of space needed for the load itself during the turning maneuver.

C. Outside Corner to Centerline of Rear Axle (R oc)

This is the distance from the centerline of the rear axle to the outermost corner (usually the front corner) of the forklift chassis. This is the definition of the actual Outside Turning Radius (R

outside ).

D. Load Length (L load) and Pallet Offset

The turning radius must account for the load being carried. For a standard 48-inch (1.2m) pallet, the total load dimension (L load) is added to the necessary pivot space.

III. The Mathematical Derivation of Minimum Aisle Width (MRAW) (Approx. 300 words)

While manufacturers provide a simple R Outside number, the MRAW is the critical dimension calculated by the facility designer using the following geometric formula, often referred to as the Right Angle Stacking Aisle (RAS) Formula.

The fundamental equation is derived from the Pythagorean theorem, considering the pivot point of the forklift (the front axle) and the necessary clearance (C).

A: Lateral operating distance (the gap between the load and the racking, typically 6 inches or 0.15m for each side, so 0.3m total).

C: Clearance factor (a safety margin, usually 12inches or 0.3m for the vehicle body to clear the racking).

Note: A simplified, more commonly cited industry formula that assumes a fixed clearance is:

MRAW≈Outside Turning Radius+Load Length+Safety Clearance

However, the geometric derivation above provides the engineering precision required for high-density, narrow-aisle applications. The squaring of the components emphasizes that both the length and width of the vehicle and its load contribute exponentially to the required turning space.

IV. Turning Radius Across Forklift Classes: A Comparative Analysis (Approx. 350 words)

The turning radius varies dramatically based on the forklift class, which is a reflection of the design trade-offs between load capacity, stability, and maneuverability.

ITA Class Forklift Type Typical Rated Capacity (lbs) Typical Outside Turning Radius (R

outside

Reach Trucks (Class II) represent the extreme of space efficiency. They do not turn 90-degrees in the aisle to deposit a load. Instead, they drive straight in, and the entire mast mechanism "reaches" out to the rack. Their R

outside

is minimized because they are designed to operate in aisles as narrow as 9feet (2.7m), directly challenging the spatial limitations of standard counterbalance trucks (12feet or 3.6m minimum).

Three-Wheel Counterbalance Trucks offer a major advantage over their four-wheel counterparts. By utilizing a single rear steering wheel (or a very tightly coupled differential pair), they can achieve a tighter pivot angle, often resulting in a radius that is up to 15% smaller than a comparable capacity four-wheel model. This configuration allows for the pivot point to be closer to the center of the chassis.

V. Operational and Financial Implications (Approx. 150 words)

The difference of a single foot in MRAW (12ft vs. 11ft) can have profound financial and logistical consequences for a facility:

Increased Storage Density: Reducing the aisle width by one foot across a 100-aisle warehouse can potentially add several new full aisles of racking, resulting in thousands of new pallet positions. This translates directly to increased revenue potential without expanding the building footprint.

Productivity and Safety: While a smaller turning radius allows for tighter aisles, it can also necessitate slower operating speeds. Operators must exercise greater precision, reducing the margin for error. Conversely, having an MRAW that is too tight for the operator's comfort can lead to higher incidence of product and rack damage.

VI. Conclusion (Approx. 100 words)

The question, "What is the turning radius of this forklift?" leads to a sophisticated analysis of vehicle dynamics, geometric constraints, and operational efficiency. The R

outside

is a manufacturer's specification, but the MRAW is the facility planner's mandate. By selecting a truck whose precise turning radius matches the required aisle width, businesses can achieve the highest possible storage density while maintaining safe and productive material flow. The geometry of maneuverability is, ultimately, the geometry of profitability.

To reach the 2000-word target, you could expand the following sections:

Detailed Case Studies (Section IV): Add two full paragraphs detailing specific real-world examples:

Case Study A: The conversion of a standard 12-foot aisle layout to a 10-foot layout using an articulating forklift (Class II), including the calculated increase in pallet positions.

Case Study B: The impact of using a very heavy, high-capacity pneumatic-tire truck (Class V) on an outdoor yard, where the turning radius is governed more by ground surface and tire slip than by chassis geometry.

Safety and Training (Section V): Dedicate a full paragraph to how operator training is affected by the turning radius, discussing practices like the "fish-tailing" of the rear steering wheels and the importance of dynamic clearance (clearance needed while turning).

Future Technologies: Discuss emerging technologies (like automated guided vehicles or AGVs and autonomous mobile robots or AMRs) where the "turning radius" is a calculated digital path, often incorporating omni-directional or skid steering, which fundamentally changes the constraints.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China