In the relentless pursuit of efficiency and optimization, modern industries are constantly seeking innovative solutions to streamline their operations. Among the myriad of technologies revolutionizing warehousing and logistics, the stacker system stands out as a pivotal component in achieving automated, high-density storage and retrieval. More than just a piece of equipment, a stacker system represents an integrated approach to material handling, designed to maximize space utilization, improve throughput, and reduce labor costs. This comprehensive technical article will delve into the intricacies of stacker systems, exploring their fundamental principles, diverse types, key components, operational mechanisms, advantages, disadvantages, and various applications across industries.

The Fundamental Concept: Vertical Storage and Automated Handling

At its core, a stacker system is an automated or semi-automated material handling solution engineered to store and retrieve goods in a vertical and dense manner. Unlike traditional warehousing, where forklifts navigate wide aisles to access pallets, stacker systems leverage height to significantly increase storage capacity within a given footprint. This verticality is achieved through a combination of specialized racks and a dedicated machine – the stacker crane – that travels horizontally and vertically to deposit or retrieve loads.

The driving force behind stacker systems is the principle of automated handling. By minimizing or eliminating manual intervention, these systems reduce the risk of human error, improve safety, and enable faster, more consistent operations. This automation can range from semi-automatic systems, where an operator initiates commands, to fully automatic systems integrated with warehouse management systems (WMS) for seamless, lights-out operation.

A Spectrum of Stacker Systems: Understanding the Types

While the fundamental concept remains consistent, stacker systems come in various configurations, each suited to different operational needs and scales. The primary classification often revolves around the type of load handled and the degree of automation.

1. Unit-Load Stacker Systems (Pallet Stacker Systems)

These are arguably the most common type of stacker systems, designed to handle unit loads, typically pallets. They are ideal for high-volume storage and retrieval of standardized goods.

Single-Deep Stacker Systems: The simplest configuration, where the stacker crane places or retrieves pallets from a single-depth rack position. While straightforward, they offer less density compared to deeper systems.

Double-Deep Stacker Systems: The stacker crane is equipped with a telescopic fork that can reach two pallet positions deep within a rack. This significantly increases storage density without requiring additional aisles.

Multi-Deep Stacker Systems (Satellite Stacker Systems): These advanced systems utilize a shuttle or satellite vehicle on the fork of the stacker crane to access multiple pallet positions (often 3 to 10 or more) within a single lane. This offers the highest storage density for unit loads, making them suitable for scenarios with many identical SKUs. The satellite vehicle transports the pallet into or out of the deep lane, while the stacker crane moves between lanes.

2. Mini-Load Stacker Systems (Case or Tote Stacker Systems)

Unlike unit-load systems that handle pallets, mini-load stacker systems are designed for smaller items, typically stored in totes, cases, or trays. They are prevalent in e-commerce fulfillment centers, manufacturing facilities, and distribution centers dealing with high volumes of individual items.

Standard Mini-Load Systems: Similar to unit-load systems, the stacker crane directly places and retrieves individual totes or cases from shelves.

Multi-Shuttle Mini-Load Systems: These are a highly dynamic and flexible evolution. Instead of a single crane, multiple independent shuttles operate on each level of the racking system. These shuttles move horizontally and transfer totes to a vertical lift, which then transports them to the pick station. This architecture offers exceptional throughput and redundancy.

3. Specialty Stacker Systems

Beyond the primary categories, specialized stacker systems cater to unique material handling challenges.

Roll Stacker Systems: Designed for storing and retrieving large rolls of material, such as paper, fabric, or steel coils.

Sheet Stacker Systems: Optimized for flat materials like metal sheets or wood panels.

Long Goods Stacker Systems: For exceptionally long items like pipes, timber, or extrusions, often utilizing cantilever racking.

Dissecting the Architecture: Key Components of a Stacker System

A fully functional stacker system is a marvel of engineering, comprising several interconnected components that work in harmony.

1. The Stacker Crane (AS/RS Machine)

The heart of the stacker system, the stacker crane is a specialized machine that travels along a rail system within the aisles. Its primary functions include:

Horizontal Movement (Travel): Propelled by electric motors, the crane moves along the length of the aisle on rails mounted on the warehouse floor.

Vertical Movement (Lift): A mast assembly, often telescopic, allows the crane to raise and lower its load handling device to any desired height within the racking structure.

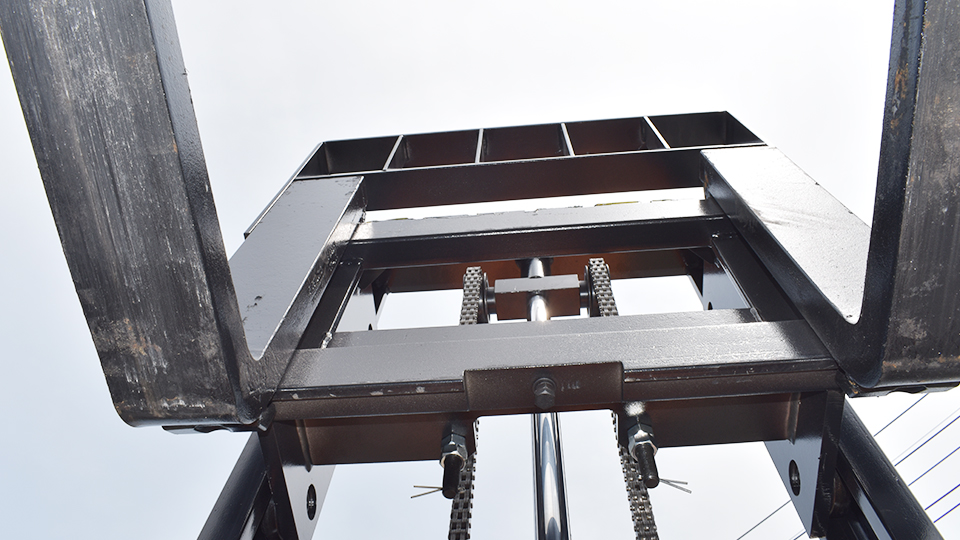

Load Handling Device (Fork or Shuttle):

Telescopic Forks: Common in unit-load systems, these extend and retract to pick up or deposit pallets.

Shuttle/Satellite Vehicles: Used in multi-deep unit-load systems, these independent vehicles travel within the rack lanes to access deep storage positions.

Extractor Mechanisms: In mini-load systems, these mechanisms are designed to grip and extract totes or cases.

Control System: Onboard controllers manage the crane's movements, safety features, and communication with the central WMS.

2. Racking Structure

The racking is the framework that holds the stored goods. It is specifically designed to integrate with the stacker crane and often built to precise tolerances.

Pallet Racking: For unit-load systems, sturdy pallet racking supports the weight of loaded pallets.

Shelving/Case Racking: For mini-load systems, specialized shelving is designed to accommodate totes or cases.

Guided Rails: Rails mounted on the floor and sometimes at the top of the racking provide the precise path for the stacker crane.

3. Conveyor Systems / Pick & Deposit (P&D) Stations

These interfaces facilitate the transfer of goods between the stacker system and other areas of the warehouse, such as inbound receiving, outbound shipping, or picking stations.

Conveyors: Automated conveyor belts transport pallets, totes, or cases to and from the P&D stations.

P&D Stations: Designated locations where the stacker crane deposits or picks up loads, often equipped with sensors and safety features.

4. Warehouse Management System (WMS) and Warehouse Control System (WCS)

These software systems are the brains of the operation.

WMS: The overarching software that manages inventory, order processing, and overall warehouse operations. It generates storage and retrieval commands for the stacker system.

WCS: A more granular control system that translates WMS commands into specific actions for the stacker crane and other automated equipment. It optimizes crane movements, manages traffic, and handles error recovery.

The Operational Symphony: How a Stacker System Works

The operation of a stacker system is a precisely choreographed sequence of events, driven by software and executed by sophisticated machinery.

Storage Process (Put-Away):

Arrival: Goods arrive at a P&D station, typically via a conveyor system.

Identification: Barcodes or RFID tags on the goods are scanned, and the WMS identifies the item and its attributes.

Location Assignment: The WMS, based on predefined rules (e.g., product velocity, size, temperature requirements), assigns an optimal storage location within the racking.

Command Transmission: The WMS sends a "put-away" command to the WCS, specifying the item and its designated location.

Crane Movement: The WCS instructs the stacker crane to travel horizontally and vertically to the assigned storage slot.

Load Deposit: The crane's load handling device (fork or extractor) extends and carefully deposits the load into the rack position.

Confirmation: Sensors confirm the successful deposit, and the WCS updates the WMS with the new inventory location.

Retrieval Process (Pick-Up):

Order Generation: An order is generated by the WMS, specifying the items to be picked.

Location Identification: The WMS identifies the storage location of the requested items.

Command Transmission: The WMS sends a "retrieval" command to the WCS.

Crane Movement: The WCS instructs the stacker crane to travel to the specified location.

Load Retrieval: The crane's load handling device extends, retrieves the load, and retracts.

Transport to P&D: The crane then transports the retrieved load back to a designated P&D station.

Outbound Flow: The retrieved goods are then transferred to another conveyor or a staging area for further processing (e.g., packing, shipping).

Confirmation: Sensors confirm the successful retrieval, and the WCS updates the WMS, reducing the inventory count for that location.

The Stacker System Advantage: Unlocking Efficiency

The adoption of stacker systems offers a compelling array of benefits that directly impact a company's bottom line and operational capabilities.

Maximized Space Utilization: This is perhaps the most significant advantage. By leveraging vertical space, stacker systems can reduce the required floor space for storage by 50% or more compared to traditional methods, especially in urban areas where real estate is expensive.

Increased Throughput and Speed: Automation eliminates manual travel time and significantly speeds up storage and retrieval operations, leading to higher throughput and faster order fulfillment.

Reduced Labor Costs: Automation significantly reduces the need for manual labor for repetitive tasks like lifting, carrying, and navigating, leading to substantial cost savings.

Improved Accuracy and Inventory Control: Integrated WMS and WCS ensure precise tracking of every item, virtually eliminating misplaced inventory and improving inventory accuracy to near 100%.

Enhanced Safety: Removing humans from hazardous tasks like operating forklifts at height significantly reduces workplace accidents and injuries.

Better Product Protection: Automated handling minimizes the risk of product damage that can occur during manual operations.

Scalability: Many stacker systems are modular, allowing for expansion as business needs grow.

24/7 Operation: Fully automated systems can operate continuously, even in lights-out environments, without the need for breaks or shifts.

Climate Control Optimization: The compact nature of AS/RS makes it easier and more cost-effective to maintain specific temperature and humidity levels for sensitive goods.

Addressing the Trade-offs: Disadvantages and Considerations

While the benefits are substantial, it's crucial to acknowledge the potential drawbacks and considerations associated with stacker systems.

High Initial Investment: The upfront capital expenditure for stacker cranes, specialized racking, software, and integration can be significant. This requires a thorough return on investment (ROI) analysis.

Complexity: Designing, implementing, and maintaining a stacker system requires specialized expertise and can be complex.

Reliance on Technology: A breakdown in the WMS, WCS, or mechanical components can halt operations. Robust maintenance programs and redundancy are essential.

Limited Flexibility (in some cases): While some systems offer flexibility, dedicated AS/RS can be less adaptable to drastic changes in product dimensions or storage requirements compared to purely manual systems.

Maintenance Requirements: Regular preventative maintenance is critical to ensure optimal performance and longevity of the sophisticated machinery.

Learning Curve: Operators and maintenance staff require specialized training to effectively manage and troubleshoot the system.

Diverse Applications Across Industries

The versatility of stacker systems makes them invaluable across a wide spectrum of industries.

E-commerce and Retail: High-volume order fulfillment of individual items (mini-load systems), quick replenishment of store inventory.

Manufacturing: Storage of raw materials, work-in-process (WIP), and finished goods, often integrated with production lines for just-in-time (JIT) delivery.

Automotive: Storage of parts, sub-assemblies, and tires.

Food and Beverage: Temperature-controlled storage of perishable goods, often in cold or freezer environments.

Pharmaceuticals: Secure and climate-controlled storage of medications, adherence to strict regulatory requirements.

Chemicals: Safe and organized storage of various chemical products, often with specific handling requirements.

Aerospace: Storage of expensive, high-value components and tooling.

Distribution Centers: Centralized storage and dispatch of a wide range of products to various destinations.

The Future of Stacker Systems: Evolution and Innovation

The evolution of stacker systems is far from over. Future trends point towards even greater sophistication, integration, and intelligence.

Increased Use of AI and Machine Learning: Predictive maintenance, optimized route planning, and dynamic slotting will be driven by AI.

Robotics Integration: More seamless integration with autonomous mobile robots (AMRs) for last-mile delivery within the warehouse and collaborative robots (cobots) for picking operations.

Enhanced Energy Efficiency: Development of more energy-efficient motors, regenerative braking systems, and smarter power management.

Modular and Scalable Designs: Easier expansion and reconfiguration to adapt to changing business demands.

IoT and Data Analytics: Greater use of sensors to collect real-time operational data for continuous optimization and performance monitoring.

Cloud-Based WMS/WCS: Greater flexibility, accessibility, and scalability of control systems.

Conclusion

A stacker system is much more than a piece of warehouse equipment; it is a strategic investment in the future of an organization's supply chain. By embracing vertical storage and advanced automation, these systems offer a powerful solution for businesses striving to achieve higher levels of efficiency, accuracy, and cost-effectiveness in their material handling operations. While the initial investment can be substantial, the long-term benefits in terms of space utilization, throughput, labor optimization, and safety make stacker systems an indispensable tool for companies looking to thrive in an increasingly competitive and demanding global marketplace. As technology continues to advance, stacker systems will undoubtedly play an even more pivotal role in shaping the warehouses of tomorrow, becoming smarter, more agile, and even more integral to the seamless flow of goods.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China