That’s a question that dives straight into the physics of material handling! Answering "What is the fulcrum or balancing point of a forklift?" requires a detailed, technical exploration of stability, the load center, and the crucial concept known as the Stability Triangle.

�� Key Factual Foundation & Technical Overview

The simple answer to the question is that a forklift's balancing point, or fulcrum, is the point around which the entire machine pivots when lifting a load.1 This point is always the center of the front axle or drive wheel centerline.

The Counterbalance Principle: Explaining how the forklift operates as a Class 1 Lever, where the load and the counterbalance weight oppose each other across the fulcrum.

Defining the Fulcrum: Precisely locating the pivot point on different types of forklifts (counterbalance vs. reach trucks).

The Stability Triangle: The cornerstone of forklift physics, detailing its vertices and what happens when the center of gravity moves outside this area.2

The Load Center and Data Plate: How the theoretical fulcrum translates into practical safety data used by operators.

�� Search Strategy for Your Technical Article

I will search for the specific technical terms, stability concepts, and relevant OSHA/HSE guidelines that discuss the balance and stability of powered industrial trucks.

The search results confirm and provide the necessary technical depth, including specific regulatory references (OSHA 29 CFR 1910.178 Appendix A), the lever class, and the precise definition of the stability triangle.

�� Technical Article Outline: The Fulcrum and Physics of Forklift Stability

I. Introduction: The Industrial Seesaw

II. The Direct Answer: State the precise fulcrum location: The center of the front axle (drive axle centerline) .

The Deeper Principle: Explain that a counterbalance forklift is essentially an industrial Class 1 Lever, where the front axle acts as the fulcrum or pivot point.3

The Three Forces: Introduce the three forces that must remain in equilibrium: The Load Weight (Resistance), the Counterweight (Effort), and the Fulcrum (Pivot).

The Risk: Highlight the danger—unlike a static crane, the forklift's center of gravity is constantly moving, which necessitates the operator's deep understanding of the fulcrum's role.

II. The Forklift as a Class 1 Lever

1. Defining the Class 1 Lever

Structure: Detail the properties of a Class 1 lever (Fulcrum is located between the effort and the resistance).4

Forklift Anatomy: Break down the machine into the lever components:

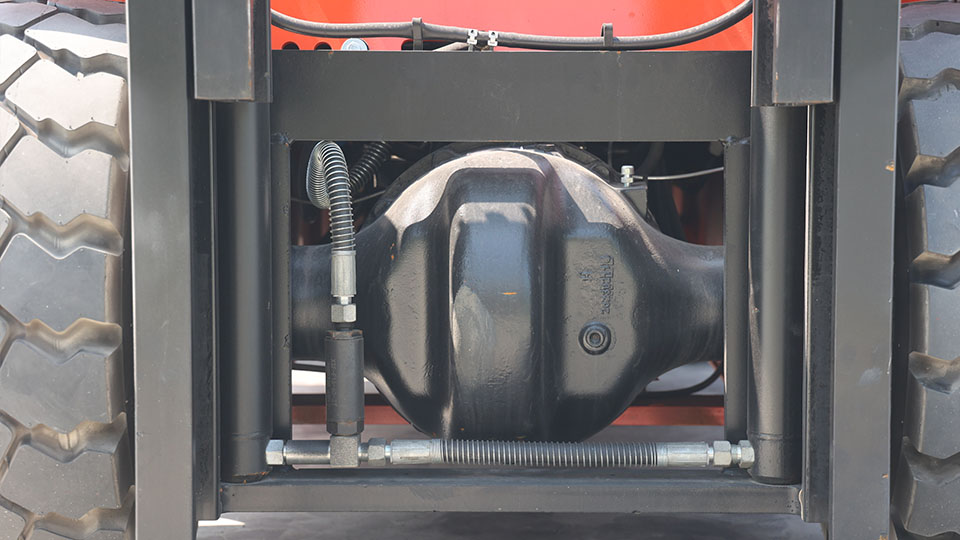

Fulcrum (Pivot): The centerline of the front axle.5

Resistance (Load Arm): The load carried on the forks (and the weight of the mast/forks themselves).6

Effort (Effort Arm): The weight of the truck's chassis, engine/battery, operator, and the massive Counterweight block at the rear.

2. The Torque Calculation (Moment)

Law of the Lever: Explain that stability is maintained when the Effort Torque (7$\tau_{Effort}$) is greater than the Resistance Torque (8$\tau_{Load}$).9

Applying it to the Forklift: The counterweight is positioned at a fixed distance (D) from the fulcrum. The load, however, moves the center of gravity (F) away from the fulcrum, increasing the Resistance Torque.10 This is why the counterweight must be significantly heavier than the load capacity.

Upending Hazard: Define Longitudinal Instability as the failure when the Resistance Torque exceeds the Effort Torque, causing the rear wheels to lift off the ground.

III. The Stability Triangle: The Foundation of Safe Operation

1. Locating the Stability Triangle's Vertices

Three Points of Contact: Explain that a typical 4-wheel counterbalanced forklift is actually supported by a three-point suspension system.11

The Points:

Point 1: The center of the pivot pin on the rear (steer) axle.

Point 2: The left front wheel (point where the tire meets the ground).12

Point 3: The right front wheel (point where the tire meets the ground).

The Rule: A forklift is stable only as long as the combined Center of Gravity (CG) of the truck and the load remains within the area of this imaginary triangle.13

2. The Combined Center of Gravity (CG)

Empty vs. Loaded:

Empty: The CG is low, near the center of the truck, well within the triangle.14

Loaded: The CG shifts dramatically forward and upward, moving toward the front axle (the base of the triangle).

Lateral Stability (Side Tip): Explain that tipping sideways (Lateral Instability) occurs when the CG moves outside the left or right boundaries of the triangle, typically caused by turning too sharply or carrying an off-center load.15

Dynamic Stability (The Pyramid): Stress that stability is three-dimensional (a stability pyramid).16 The higher the load is lifted, the higher the combined CG moves, making the base of the triangle smaller in effect and the machine exponentially easier to tip sideways.

3. OSHA Guidance and the Data Plate

Regulatory Basis: Reference the importance of this concept under OSHA 29 CFR 1910.178 Appendix A, which mandates that operators must be trained on how stability is affected by the load's placement.17

The Safe Zone: OSHA recommends carrying the load at the lowest position possible (4 to 6 inches from the ground) while traveling to keep the CG low and centered.18

IV. Load Center: The Fulcrum's Critical Distance

1. Defining the Load Center Distance

The Manufacturer's Specification: Explain that a forklift's capacity is not a static number, but a dynamic one based on a specific, predetermined Load Center (LC).19

Load Center Definition: The horizontal distance measured from the vertical face of the forks to the center of gravity of the load.20 The industry standard is often 21$\mathbf{24 \text{ inches}}$.22

Why LC is Vital: As the load moves further out (increasing the distance, D, in the torque equation), the fulcrum's stability is compromised, and the actual capacity of the forklift decreases (derates) dramatically.

2. Reading the Data Plate (Nameplate)

The Key Information: Detail what the operator must know: The data plate specifies the maximum weight capacity at a specified Load Center Distance and Max Lift Height.23

The Danger of Exceeding the LC: Using a long, irregularly shaped load that moves the CG beyond the rated load center distance will overload the forklift, even if the load's weight is below the stated capacity. This shift is what forces the CG outside the stability triangle.

V. Advanced Stability Concepts and Operator Action

1. Factors That Shift the CG (and Challenge the Fulcrum)

Acceleration and Braking: Sudden stopping shifts the CG violently forward (increasing the risk of longitudinal tip-over).

Turning: Sharp turns shift the CG laterally outward (increasing the risk of lateral tip-over).24

Ramps and Grades: Driving a forklift up or down an incline significantly shortens the Stability Triangle on one side, making turns on grades exceptionally dangerous (never turn on a ramp).25

Attachments: Any attachment (side shifters, drum clamps) adds weight forward of the fulcrum and often requires a derated capacity plate from the manufacturer.26

2. The Operator’s Role as the Stability Manager

The operator is the only variable that controls the CG's movement. Safe operation is the continuous, conscious effort to keep the combined CG as close as possible to the center of the Stability Triangle.27

Immediate Tip-Over Protocol: Briefly mention the critical safety instruction: Never jump from an overturning forklift; stay in the cab, brace yourself, and lean away from the impact, as the overhead guard offers the best protection.

VI. Conclusion: Respecting the Pivot

Summary: The fulcrum (front axle) is the physical pivot, but the Stability Triangle is the theoretical boundary of safety.

The Technical Takeaway: The entire physics of the counterbalance forklift is designed to ensure the massive weight behind the front axle exerts a greater torque than the load in front of it.28

Final Call: Understanding the fulcrum and the dynamic nature of the CG is the single most important piece of technical knowledge for preventing accidents and ensuring the machine performs its industrial balancing act safely.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China