Introduction to Forklift Mass and Operational Weight

The question, "How much does a Toyota forklift weigh?" does not yield a single, simple answer. The operational mass of a powered industrial truck (PIT), commonly known as a forklift or lift truck, is a critical engineering and safety specification that varies enormously across the manufacturer’s product line. Toyota Material Handling, a global leader in material handling equipment, produces a comprehensive array of forklifts, each designed for a specific load capacity, lift height, and operating environment.

The total Operating Weight of a forklift is not merely its empty mass, but a fundamental parameter in its function, directly correlating with its load capacity and stability. For counterbalanced forklifts, the weight of the truck itself serves as the counterbalancing mass required to offset the weight of the load being lifted. This technical article will systematically dissect the weight specifications of Toyota forklifts, categorizing them by power type and application, and detailing the critical components and engineering principles that dictate their final mass.

Part I: Categorical Analysis of Toyota Forklift Weights

Toyota’s product offerings can be broadly divided into three major categories, each with distinct weight profiles determined by their design requirements.

1. Light-Duty/Warehouse Equipment (Walkie/Rider)

This class of equipment is designed for indoor use, focused on maneuverability, and operates without the traditional massive counterweight of a counterbalance truck. Their operational mass is relatively low, making them suitable for multi-story buildings, mezzanine levels, and general warehouse flooring where point loading is a concern.

|

Equipment Type |

Typical Load Capacity (LBS / kg) |

Approximate Operating Weight (LBS / kg) |

Key Weight Component |

|

Electric Walkie Pallet Jack (e.g., 8HBW23) |

4,500 LBS / 2,041 kg |

600–1,200 LBS / 272–544 kg (varies with battery) |

Battery and structural steel |

|

Walkie Reach Truck/Stacker (e.g., WS1-RE30) |

3,000 LBS / 1,360 kg |

2,500–4,000 LBS / 1,133–1,814 kg (includes outriggers) |

Chassis, motor, and battery |

|

Stand-Up Rider Counterbalance (e.g., 4000 Series) |

3,000–4,500 LBS / 1,360–2,041 kg |

5,500–8,500 LBS / 2,495–3,855 kg (Battery is primary CWT) |

Heavy-duty traction battery |

For walkie-style equipment, the weight is not primarily for counterbalancing; instead, it is necessary for traction and structural integrity to support the load on the outriggers or forks. The weight of the battery in electric models contributes significantly, often accounting for a large percentage of the total operating mass.

2. Mid-Capacity Counterbalance Forklifts (The Core Line)

This represents the most common class of forklifts, utilized in nearly all warehousing, manufacturing, and distribution applications. The weight of these machines is heavily engineered to meet the strict demands of the Stability Triangle and the required load capacity.

A. Core Electric Counterbalance Forklifts

In electric counterbalanced trucks, the heavy lead-acid or lithium-ion traction battery is a dual-purpose component: it provides power and acts as the primary counterweight. This integration results in a higher density of mass and a more compact design compared to IC trucks of the same capacity.

|

Model Class |

Typical Load Capacity (LBS / kg) |

Approximate Operating Weight (LBS / kg) |

Weight Variance Factors |

|

Core Electric (3-Wheel/4-Wheel) |

3,000–6,500 LBS / 1,360–2,950 kg |

6,500–12,000 LBS / 2,950–5,443 kg |

Battery capacity (voltage/amp-hour), mast height/type. |

|

Large Electric (e.g., 7FBCU) |

8,000–12,000 LBS / 3,628–5,443 kg |

15,000–22,000 LBS / 6,800–9,980 kg |

Chassis size, motor rating, and significantly larger counterweight. |

Example Technical Breakdown (Approximate):

A 5,000 LBS (2,268 kg) capacity 4-wheel electric forklift typically has an operating weight of about 9,500 LBS (4,300 kg). This mass is distributed to ensure a high level of longitudinal and lateral stability according to ANSI/ITSDF standards.

B. Core Internal Combustion (IC) Counterbalance Forklifts

IC trucks (powered by LPG, gasoline, or diesel) use a dedicated, cast-iron counterweight (CWT) bolted to the rear of the truck to provide the necessary stability. This CWT mass is often significantly heavier than the engine and fuel components.

|

Model Class |

Typical Load Capacity (LBS / kg) |

Approximate Operating Weight (LBS / kg) |

Weight Variance Factors |

|

Core IC Pneumatic (e.g., 8FGU series) |

3,000–6,500 LBS / 1,360–2,950 kg |

5,500–11,500 LBS / 2,500–5,216 kg |

Tire type (pneumatic vs. cushion), engine type, mast configuration. |

|

Core IC Cushion (e.g., 8FGCU series) |

3,000–6,500 LBS / 1,360–2,950 kg |

5,000–11,000 LBS / 2,268–4,990 kg |

Cushion tires often allow for a slightly lower profile and mass. |

Example Technical Breakdown (Based on 40-8FGU18):

A Core IC Pneumatic with 3,500 LBS (1,600 kg) capacity has a Total Weight (unloaded) of approximately 6,090 LBS (2,760 kg). This weight is carefully distributed with a significant portion over the steer axle to maintain stability when the load is elevated.

3. Heavy-Duty and High-Capacity Models

For applications such as ports, steel mills, and heavy manufacturing, Toyota produces High-Capacity forklifts (THD models) with dramatically increased weights, necessitated by the required load moment.

|

Model Class |

Typical Load Capacity (LBS / kg) |

Approximate Operating Weight (LBS / kg) |

|

Large IC Cushion |

15,000–22,000 LBS / 6,804–9,979 kg |

30,000–45,000 LBS / 13,608–20,412 kg |

|

High-Capacity IC |

25,000–100,000 LBS / 11,340–45,359 kg |

40,000–120,000+ LBS / 18,144–54,431+ kg |

The largest models in this class, capable of lifting up to 100,000 LBS, become massive, multi-axle machines whose operating weight can easily exceed 80,000 LBS (36,287 kg), rivaling the weight of heavy construction equipment. Their engineering is focused on structural rigidity, massive counterweights, and robust powertrain components to handle immense forces.

Part II: Technical Determinants of Forklift Mass

The weight of a Toyota forklift is not arbitrary; it is a calculated engineering variable derived from the principles of lever physics and the concept of the Stability Triangle.

1. The Principle of Counterbalance and Load Moment

A forklift operates as a Class 1 Lever, with the front axle (or the centerline of the drive wheels) acting as the fulcrum. The force exerted by the load (the Load Moment) must be counterbalanced by the opposing force of the truck’s mass (the Truck Moment).

$$\text{Load Moment} = \text{Load Weight} \times \text{Load Center Distance}$$

$$\text{Truck Moment} = \text{Truck Weight (less components forward of the fulcrum)} \times \text{Counterweight Arm Length}$$

To ensure stability, the Truck Moment must always exceed the Load Moment by a significant margin as defined by engineering standards (e.g., ASME B56.1, ISO 22915). Therefore, the final operating weight is a direct function of the rated load capacity and the standard load center (typically 24 inches/600 mm). The heavier the required lift, the heavier the necessary counterweight, and thus, the heavier the overall machine.

2. The Influence of Core Components on Mass

Several major sub-assemblies contribute disproportionately to the forklift's total mass:

A. The Counterweight (CWT)

This is the single heaviest non-load-bearing component on most counterbalance forklifts. It is a dense, precision-cast block of steel or iron, designed with specific dimensions and density to place the combined center of gravity (CCG) of the loaded truck safely within the Stability Triangle. Its mass is non-negotiable and dictated by the truck's rated capacity.

B. The Power Source

Electric Models: The traction battery is a major mass component. A typical $48\text{V}, 840\text{Ah}$ industrial lead-acid battery for a $5,000\text{ LBS}$ capacity truck can weigh over 2,500 LBS (1,134 kg). This weight is strategically located low and rearward in the chassis to optimize the CCG. Lithium-ion batteries, while lighter for the same power, still contribute substantial mass, though the total truck weight may be slightly lower or require supplemental counterweight.

Internal Combustion (IC) Models: The engine, transmission, and drivetrain are heavy, but the absence of a large battery necessitates a much larger, separate cast-iron counterweight to compensate.

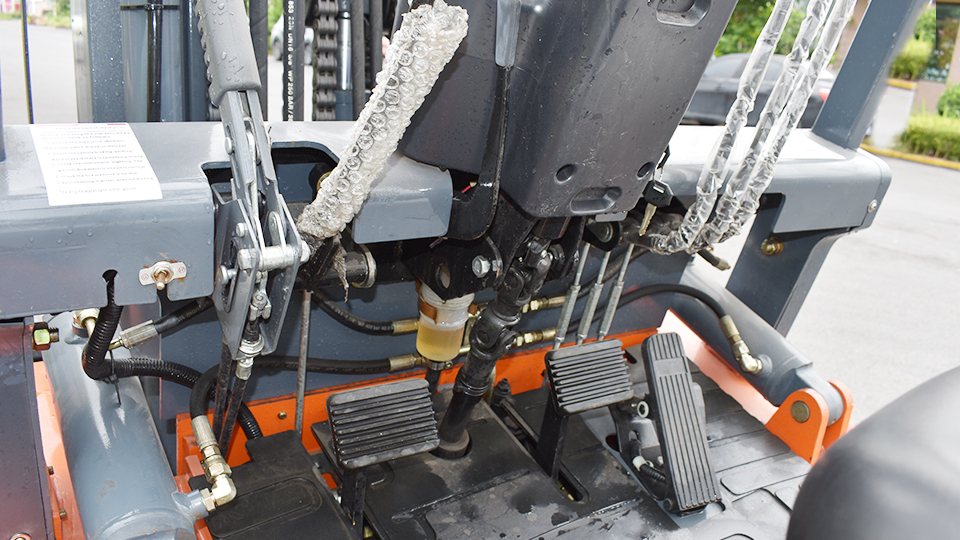

C. The Mast Assembly

While the main chassis and counterweight provide stability, the mast contributes to mass, especially on high-reach models. A mast's structure (two-stage, three-stage, quad) must withstand significant compressive and bending stresses. High-lift masts utilize more robust, thicker-gauge steel profiles and additional hydraulic cylinders, substantially increasing the total forward-mounted mass. This forward mass requires a corresponding increase in the rear counterweight mass to maintain balance.

D. The Chassis and Drivetrain

Heavy-duty applications demand thicker steel frames, larger drive axles, and more robust transmissions. For instance, a Toyota High-Capacity IC forklift utilizes a heavy-duty planetary drive axle and a high-horsepower engine, all of which add significant mass compared to a light-duty warehouse unit.

Part III: The Operational Significance of Forklift Weight

The weight of a Toyota forklift is more than just a specification; it is a critical parameter influencing its operational performance, safety, and infrastructure impact.

1. Safety and Stability Engineering

The entire design principle of a counterbalanced forklift revolves around its weight and the resulting forces. Toyota’s System of Active Stability (SAS)™ and Operator Presence Sensing System (OPSS) are electronic systems designed to monitor the truck’s longitudinal and lateral stability in real-time. These systems operate based on the truck's known, unloaded operating weight and the calculated effects of the load. Any modification that alters the fundamental mass or its distribution (e.g., adding a heavy attachment without reducing capacity, or using a non-standard counterweight) critically compromises the engineered safety margin. The truck’s Data Plate (Nameplate) displays the maximum capacity, which is strictly tied to the factory-engineered operating weight.

2. Infrastructure Impact (Point Loading)

The final operating weight dictates the forklift's interaction with flooring and ground surfaces. The concept of Point Loading—the maximum weight concentrated on a small area (the tire contact patch)—is crucial for:

Warehouse Flooring: Concrete slab thickness and reinforcement must be specified to handle the combined weight of the forklift and its maximum load. Excessive point loading can lead to concrete cracking or failure.

Trailer/Dock Plates: The gross vehicle weight (GVW = Operating Weight + Max Load) must be less than the rated capacity of dock plates, ramps, and the trailer floor itself to prevent structural collapse.

Elevators: Operating weight is the primary factor in determining if a forklift can be safely moved via freight elevator.

3. Energy Efficiency and Performance

In electric forklifts, the substantial mass of the battery (the counterweight) directly impacts energy consumption. Every acceleration and deceleration cycle requires energy to manage the inertia of this mass. Similarly, IC forklifts must overcome the inertia of their heavy counterweights, affecting fuel consumption. Toyota engineers optimize the weight distribution not just for stability, but also for performance metrics like travel speed, lift speed, and gradeability (the ability to climb an incline). A heavier truck requires more powerful drive motors or engines to achieve equivalent performance on a grade.

Conclusion

The weight of a Toyota forklift is a highly variable and technically calculated figure. It is not an incidental measurement but the very core of its engineering, dictated by the fundamental laws of physics applied to the material handling task.

The weight spectrum is:

Low-Range (Walkies/Stackers): $\sim 600\text{ to } 4,000\text{ LBS}$.

Core Counterbalance (Electric/IC): $\sim 5,000\text{ to } 22,000\text{ LBS}$.

Heavy-Duty/High-Capacity: $\sim 30,000\text{ to over } 120,000\text{ LBS}$.

For any specific operation, the true operating weight is the most vital piece of technical information, directly influencing safety protocols, facility design, and operational costs. An understanding of the relationship between the machine’s empty weight, its counterweight, and its rated load capacity is essential for all stakeholders in the material handling industry. The weight of a Toyota forklift is, fundamentally, the physical manifestation of its engineered lifting capability.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China