Forklifts are indispensable tools in warehouses, manufacturing plants, construction sites, and logistics centers worldwide, designed to lift and move heavy loads with precision. However, their ability to operate safely and efficiently hinges on a fundamental mechanical principle: the fulcrum and the balance of forces. For forklift operators, trainers, and maintenance technicians, understanding “where is the fulcrum of a forklift” is not just a technical detail—it is critical to preventing tip-overs, protecting personnel, and extending the lifespan of the equipment.

This technical article explores the definition of a forklift’s fulcrum, its exact location (and how it varies by forklift type), the role it plays in load stability, and the practical implications for safe operation. We will break down complex mechanical concepts into accessible explanations, supported by real-world examples and technical specifications, to help industry professionals master this essential aspect of forklift mechanics.

1. What Is a Fulcrum, and Why Does It Matter for Forklifts?

In mechanics, a fulcrum is the fixed point around which a lever rotates. For forklifts, which function as class III levers (where the effort is applied between the fulcrum and the load), the fulcrum serves as the pivot point that balances the weight of the forklift itself, the operator, and the load being lifted. Unlike a simple lever (e.g., a seesaw), a forklift’s fulcrum is not a single, visible point—but rather a defined area or axis that shifts slightly based on the forklift’s design and operating conditions.

The fulcrum is the foundation of forklift stability. Every time a forklift lifts a load, two opposing forces act around the fulcrum: • The counterweight force: The weight of the forklift’s counterweight (located at the rear of the vehicle) and the vehicle’s own mass, which pushes downward on the rear tires, creating a stabilizing moment. • The load force: The weight of the load being lifted, which pushes downward on the forks (located at the front of the vehicle), creating a tipping moment that threatens to tip the forklift forward.

A forklift remains stable as long as the counterweight force is greater than the load force. If the load force exceeds the counterweight force, the forklift will tip forward around the fulcrum—a dangerous and often catastrophic accident. This is why understanding the fulcrum’s location is critical: it determines the forklift’s load capacity, lifting height limits, and safe operating parameters.

2. The Exact Location of a Forklift’s Fulcrum

Contrary to common misconception, the fulcrum of a forklift is not the center of the rear tires or the counterweight. Instead, it is defined by the tire contact points with the ground—specifically, the outer edges of the rear tires (for most standard forklifts) or the axis of the rear wheel assembly. To be precise: The fulcrum of a standard counterbalance forklift (the most common type) is the imaginary line connecting the outer edges of the two rear tires.

Let’s break this down in detail, focusing on the most widely used forklift types:

2.1 Counterbalance Forklifts (Standard Indoor/Outdoor Models)

Counterbalance forklifts—including electric, diesel, and LPG models—are the most common type of forklift, accounting for over 80% of all forklifts in use worldwide. Their fulcrum is the easiest to identify, as it is directly tied to their rear tire configuration.

Key details about the fulcrum location for counterbalance forklifts: • Static fulcrum (no load lifted): When the forklift is stationary and no load is lifted, the fulcrum is the imaginary line connecting the outer edges of the rear tires. The forklift’s center of gravity (CG) is located between the front and rear tires, slightly toward the counterweight, ensuring stability. • Dynamic fulcrum (load lifted): When the forklift lifts a load, the center of gravity shifts forward toward the forks. As a result, the fulcrum effectively moves slightly forward, but it still remains anchored to the rear tire contact points. The rear tires bear the majority of the weight (counterweight + vehicle mass), while the front tires bear the load weight—all balanced around the rear tire fulcrum line.

Technical Note: For counterbalance forklifts with dual rear tires (a common design for heavy-duty models), the fulcrum line is the outer edge of the outer rear tires. For single rear tires (rare in modern forklifts), the fulcrum is the axis of the rear tire itself.

2.2 Reach Forklifts (Narrow Aisle Models)

Reach forklifts are designed for narrow aisle operations (e.g., in high-rack warehouses) and have a unique design that affects their fulcrum location. Unlike counterbalance forklifts, reach forklifts have a telescoping mast that extends forward to reach loads stored at high heights, and their counterweight is smaller (since they rely on a different stability mechanism).

The fulcrum of a reach forklift is the imaginary line connecting the outer edges of the front tires—the opposite of standard counterbalance forklifts. This is because reach forklifts are designed to “reach” forward, so their stability depends on the front tires as the pivot point. The rear of the reach forklift is equipped with outriggers or stabilizers (small wheels) that provide additional support, but these do not serve as the primary fulcrum.

When a reach forklift extends its mast to lift a load, the load force acts forward of the front tire fulcrum line. The forklift’s own mass and the counterweight (located at the rear) create a stabilizing moment that balances the load force, preventing the forklift from tipping backward.

2.3 Rough-Terrain Forklifts

Rough-terrain forklifts are designed for outdoor use on uneven surfaces (e.g., construction sites, gravel yards) and have larger, more rugged tires than standard forklifts. Their fulcrum location is similar to counterbalance forklifts but is adapted to their heavy-duty design.

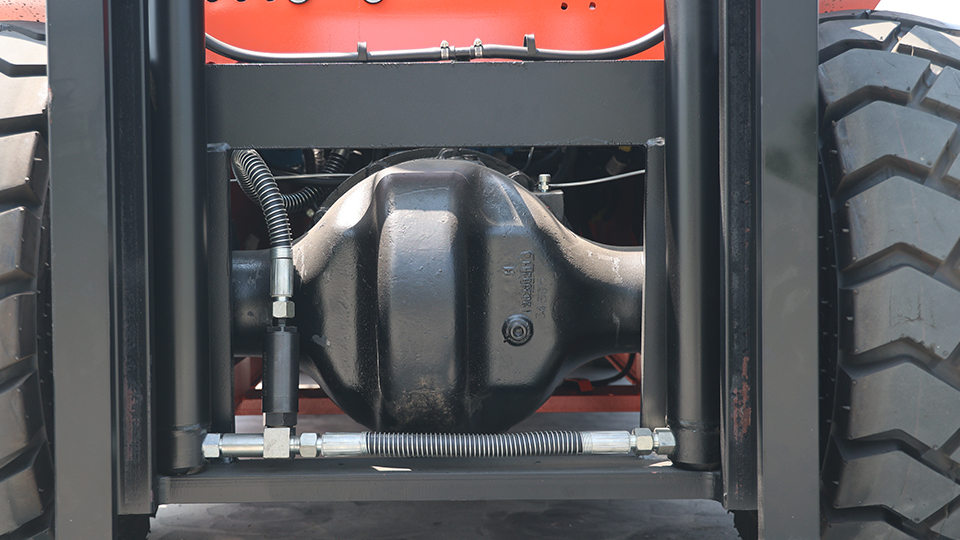

The fulcrum of a rough-terrain forklift is the imaginary line connecting the outer edges of the rear drive tires. These forklifts have a heavier counterweight (to compensate for outdoor loads and uneven terrain) and wider rear tires, which expand the fulcrum line and improve stability. The front tires are smaller and more maneuverable, but they do not serve as the fulcrum—instead, they bear the load weight, while the rear tires and counterweight provide stability.

A key difference for rough-terrain forklifts is that their fulcrum line is more robust due to the wider rear tires, allowing them to handle uneven surfaces without shifting the pivot point excessively. However, uneven terrain can still alter the balance of forces around the fulcrum, making careful operation critical.

2.4 Specialty Forklifts (Pallet Jacks, Order Pickers)

Specialty forklifts have unique fulcrum locations tailored to their specific functions:

- Pallet jacks (manual and electric): For manual pallet jacks, the fulcrum is the axis of the front wheels (the load wheels). When you pump the handle to lift the load, the pallet jack rotates around the front wheel fulcrum, lifting the load off the ground. Electric pallet jacks have a similar fulcrum, but the motor assists with lifting, reducing the effort required.

- Order pickers: Order pickers (used for picking items from high shelves) have a fulcrum located at the rear tires, similar to counterbalance forklifts. However, since the operator stands on a platform that lifts with the load, the center of gravity shifts significantly—making the fulcrum’s location even more critical for stability.

3. How Forklift Design Affects Fulcrum Location and Stability

A forklift’s design directly influences the location of its fulcrum and its overall stability. Manufacturers carefully engineer three key components to optimize the fulcrum’s performance:

3.1 Counterweight Placement and Size

The counterweight is the single most important component affecting the fulcrum and stability. Located at the rear of the forklift, the counterweight’s mass and distance from the fulcrum determine the counterweight force. • A heavier counterweight increases the stabilizing moment, allowing the forklift to lift heavier loads. • A counterweight placed farther from the fulcrum (i.e., farther back on the forklift) also increases the stabilizing moment, as the lever arm (distance from fulcrum to counterweight) is longer.

For example, a heavy-duty counterbalance forklift (capacity 10,000+ pounds) will have a larger, heavier counterweight positioned farther back than a light-duty forklift (capacity 3,000 pounds). This design ensures that the counterweight force can balance the heavier load force acting around the fulcrum.

3.2 Wheelbase and Track Width

The wheelbase (distance between the front and rear tires) and track width (distance between the two rear tires) directly affect the fulcrum line and stability. • A longer wheelbase increases the distance between the front tires (load side) and the rear tires (fulcrum side), reducing the tipping moment and improving stability. • A wider track width expands the fulcrum line (the imaginary line between the rear tires), making it harder for the forklift to tip sideways around the fulcrum.

Narrow-aisle forklifts (e.g., reach forklifts) have a shorter wheelbase and narrower track width to fit in tight spaces, but this reduces their stability—hence their lower load capacities compared to standard counterbalance forklifts.

3.3 Mast Design and Lifting Height

The mast (the vertical assembly that lifts the forks) also affects the fulcrum and stability. As the mast extends upward, the load’s center of gravity moves higher and farther forward, increasing the tipping moment around the fulcrum. • For standard counterbalance forklifts, the maximum lifting height is limited by the fulcrum’s location—lifting a load too high can shift the center of gravity forward beyond the fulcrum, causing a tip-over. • Reach forklifts have a telescoping mast that extends forward, which shifts the load’s center of gravity even farther from the fulcrum—requiring a different fulcrum location (front tires) to maintain stability.

4. Practical Implications: Fulcrum Location and Safe Forklift Operation

Understanding the fulcrum’s location is not just a technical exercise—it directly impacts how operators must handle forklifts to avoid accidents. Below are the key practical implications for safe operation:

4.1 Load Capacity and Load Center

Every forklift has a rated load capacity, which is determined by the fulcrum’s location, counterweight size, and wheelbase. The rated load capacity is the maximum weight the forklift can safely lift at a specified load center (the distance from the front face of the forks to the center of the load).

For example, a standard counterbalance forklift with a rated capacity of 5,000 pounds at a 24-inch load center can safely lift 5,000 pounds if the load’s center of gravity is 24 inches from the forks. If the load is longer or heavier, the load center shifts forward, increasing the tipping moment around the fulcrum—and the forklift’s effective load capacity decreases.

Operators must never exceed the rated load capacity or load center, as this will unbalance the forces around the fulcrum and lead to a tip-over.

4.2 Tipping Hazards and How to Avoid Them

The most common forklift accidents involve tipping, which occurs when the load force exceeds the counterweight force around the fulcrum. The following scenarios increase the risk of tipping and should be avoided:

- Lifting a load heavier than the rated capacity: This creates an excessive tipping moment that the counterweight cannot balance.

- Lifting a load too high: As the load rises, its center of gravity moves higher, increasing the tipping moment.

- Turning too quickly: Sudden turns shift the load’s center of gravity sideways, potentially tipping the forklift around the fulcrum (sideways tip-over).

- Operating on uneven terrain: Uneven surfaces shift the forklift’s center of gravity and alter the fulcrum’s effective location, increasing tipping risk.

- Overloading the forks: Distributing the load unevenly or placing it too far forward on the forks shifts the load center beyond the safe limit.

To avoid tipping, operators should: • Always check the forklift’s load capacity chart before lifting a load. • Keep the load as low as possible when traveling. • Turn slowly and smoothly. • Avoid sudden stops or accelerations. • Operate only on level, stable surfaces (for standard forklifts).

4.3 Maintenance and Fulcrum Stability

Regular maintenance is critical to ensuring the fulcrum remains effective and the forklift stays stable. Key maintenance tasks related to the fulcrum include:

- Checking tire pressure and condition: Underinflated or worn tires reduce the tire contact area with the ground, altering the fulcrum line and reducing stability. Rear tires (the fulcrum side) should be inspected regularly for wear, cuts, or damage.

- Inspecting the counterweight: Ensure the counterweight is securely fastened and has not been damaged or modified. A loose or damaged counterweight will reduce the stabilizing moment around the fulcrum.

- Checking wheel alignment: Misaligned rear tires can shift the fulcrum line, leading to uneven weight distribution and increased tipping risk.

- Inspecting the mast and forks: A bent mast or damaged forks can shift the load’s center of gravity, unbalancing the forces around the fulcrum.

5. Common Misconceptions About Forklift Fulcrums

Even experienced industry professionals often hold misconceptions about forklift fulcrums. Below are the most common myths, debunked:

Myth 1: The fulcrum is the counterweight.

Reality: The counterweight is a stabilizing component, not the fulcrum. The fulcrum is the pivot point (rear tire line for standard forklifts), while the counterweight provides the force to balance the load around that pivot.

Myth 2: The fulcrum is a single point.

Reality: For most forklifts, the fulcrum is an imaginary line connecting the outer edges of the rear tires (or front tires for reach forklifts)—not a single point. This line provides a stable pivot area that distributes the forces evenly.

Myth 3: All forklifts have the same fulcrum location.

Reality: Fulcrum location varies by forklift type. Counterbalance forklifts have a rear tire fulcrum, reach forklifts have a front tire fulcrum, and specialty forklifts (e.g., pallet jacks) have unique fulcrum locations tailored to their design.

Myth 4: The fulcrum does not change during operation.

Reality: While the fulcrum’s basic location (rear/front tire line) remains fixed, its effective position shifts slightly based on the load’s height, position, and the forklift’s movement. For example, lifting a load higher shifts the center of gravity forward, altering the balance of forces around the fulcrum.

6. Conclusion

The fulcrum of a forklift is the critical pivot point that determines the vehicle’s stability, load capacity, and safe operating parameters. For standard counterbalance forklifts (the most common type), the fulcrum is the imaginary line connecting the outer edges of the rear tires—around which the counterweight force and load force balance to keep the forklift stable.

Understanding the fulcrum’s location is not just a technical requirement—it is a safety imperative. Forklift operators must recognize how the fulcrum affects load stability, avoid exceeding rated capacities, and follow safe operating practices to prevent tipping. Trainers and maintenance technicians must ensure that operators are educated on fulcrum mechanics and that forklifts are properly maintained to preserve fulcrum integrity.

By mastering the concept of the forklift’s fulcrum, industry professionals can improve workplace safety, reduce equipment damage, and maximize operational efficiency. Whether you are an operator, trainer, or maintenance technician, this knowledge is essential to excelling in the material handling industry.

Remember: The fulcrum is not just a mechanical detail—it is the backbone of safe forklift operation. Take the time to understand its location, how it works, and how to protect it, and you will ensure a safer, more productive workplace for everyone.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China