1. The Daily Pre-Shift Inspection

OSHA and international safety standards require a visual and functional check before every shift. This is the frontline of defense against expensive repairs.

Visual Walkaround

Leak Detection: Check the floor for "telltale" puddles. Amber fluid is usually engine oil, red is transmission or power steering fluid, and blue/green is coolant.

Tire Condition: Ensure pneumatic tires are at the correct pressure (often 100+ PSI for heavy loads). Check solid tires for "chunking" or flat spots.

Mast and Chains: Inspect for "shiny" wear patterns on the mast channels and ensure lifting chains are well-greased and free of cracked links.

Fluid Level Verification

Engine Oil: The dipstick should show oil between the "Add" and "Full" marks. Diesel oil will turn black almost immediately after an oil change; this is normal due to carbon soot suspension.

Hydraulic Fluid: Check levels with the forks fully lowered.

Coolant: Inspect the overflow reservoir. Never open a hot radiator cap.

2. Fuel System Maintenance

Diesel fuel systems are highly sensitive to two enemies: water and air.

Managing the Water Separator

Diesel fuel is hygroscopic (absorbs moisture). Modern forklifts include a water separator—a clear bowl beneath the fuel filter.

Maintenance: Drain the water separator daily if the "Water in Fuel" light illuminates.

The Danger: Water in the fuel injectors can cause "tip-blowing" due to the rapid expansion of steam at high pressures.

Fuel Filter Intervals

Replace fuel filters every 500 hours. If you operate in a dusty yard, shorten this to 250 hours.

Pro Tip: When changing a diesel filter, always "prime" the system using the manual hand pump (primer bulb) to remove air. A single air bubble in a high-pressure common rail system can prevent the engine from starting.

3. Oil and Lubrication Protocols

Oil is the lifeblood of the diesel engine, acting as a lubricant, a coolant, and a cleaner for combustion byproducts.

Engine Oil (Every 250–500 Hours)

Oil Grade: Use a high-quality 15W-40 or 5W-40 diesel-specific oil (API CK-4 or CJ-4). These oils contain additives to manage the high soot levels inherent in diesel combustion.

Filter Change: Always replace the oil filter simultaneously with the oil.

Chassis and Mast Greasing (Monthly)

Forklifts have dozens of "zerk" fittings. These must be greased to prevent metal-on-metal grinding:

Mast Channels: Apply a specialized "heavy-duty" mast grease.

Steer Axle: Diesel forklifts carry the counterweight over the steer axle; without grease, the kingpins will seize under the weight.

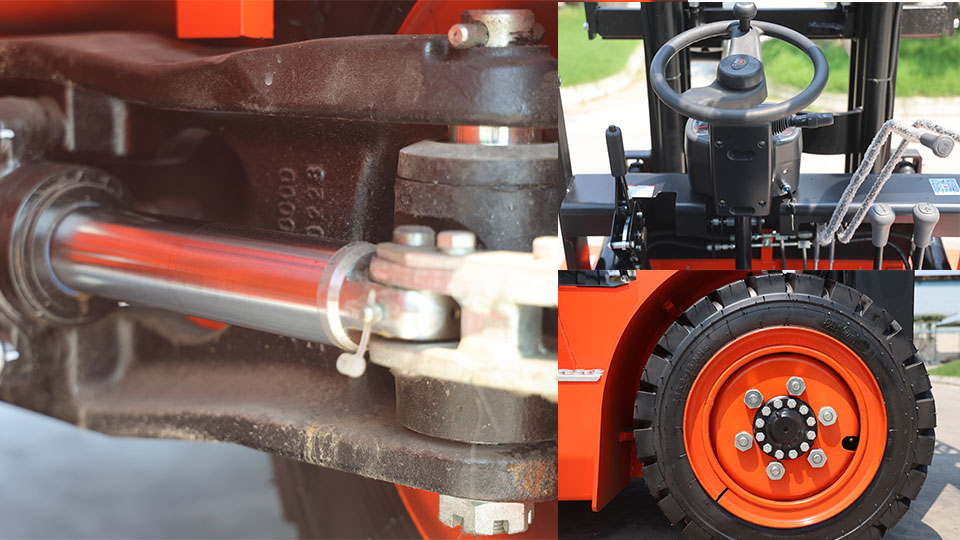

Tilt Cylinders: Ensure the pivot pins are lubricated to allow smooth tilting.

4. The 2,000-Hour "Major" Service

Every 2,000 operating hours (typically once a year for single-shift operations), the forklift requires a comprehensive "top-to-bottom" service.

|

Component |

Action Required |

|

Hydraulic System |

Complete fluid flush and return-filter replacement. |

|

Cooling System |

Drain and replace engine coolant (antifreeze). |

|

Transmission |

Replace transmission fluid and internal screen/filter. |

|

Differential |

Change the heavy gear oil in the front drive axle. |

|

Brakes |

Flush brake fluid and inspect shoe thickness. |

5. Air Intake and Cooling Systems

A diesel engine consumes thousands of cubic feet of air. In dusty environments, the air filter is the most critical component for longevity.

Air Filter: Do not just "blow out" an air filter with compressed air, as this can create microscopic holes that let dust through. If the filter is dark or the "restriction indicator" is red, replace it.

Radiator Cleaning: Diesel forklifts used in recycling or wood yards act like giant vacuum cleaners. Use compressed air to blow out the radiator fins from the engine side outward every week to prevent overheating.

6. Summary Maintenance Schedule

|

Interval |

Key Tasks |

|

Daily |

Check oil/coolant, drain water separator, test lights/brakes. |

|

250 Hours |

Engine oil & filter change, grease chassis, clean air filter. |

|

500 Hours |

Fuel filter replacement, check belt tension, inspect battery. |

|

1,000 Hours |

Inspect mast chain stretch, check engine timing, service transmission. |

|

2,000 Hours |

Full fluid flush (Hydraulic, Coolant, Brake, Differential). |

Conclusion

Consistent maintenance of a diesel forklift reduces the "Total Cost of Ownership" (TCO) by preventing the two most expensive repairs: engine overhauls and hydraulic pump replacements. By sticking to a 250-hour minor and 2,000-hour major service cycle, you ensure your machine remains a reliable asset for a decade or more.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China