Technical Compliance Roadmap: Achieving and Maintaining OSHA Forklift Certification

Abstract

Operating a powered industrial truck (PIT), commonly referred to as a forklift, is a critical function in logistics, manufacturing, and warehousing sectors. The legal authorization to perform this function is strictly controlled by the U.S. Occupational Safety and Health Administration (OSHA) under the Powered Industrial Truck Standard (29 CFR 1910.178(l)). This technical article provides a rigorous analysis of the certification process, defining the core requirement as a mandatory, three-stage training program. It clarifies the non-delegable responsibility of the employer to issue the final certification, which is site- and equipment-specific, and outlines the mandatory documentation, refresher training mandates, and the severe penalties associated with non-compliance. The ultimate goal is to provide a comprehensive compliance roadmap for safety professionals, human resources personnel, and aspiring operators.

1. Introduction: Deconstructing the Term "OSHA Certified"

The term "OSHA Certified" is commonly used but often misunderstood. OSHA itself does not issue licenses, nor does it officially "certify" individuals. Instead, OSHA mandates that employers must train, evaluate, and formally certify that each operator is competent to operate a powered industrial truck safely in their specific workplace. The certification is an employer-issued compliance document, not a government-issued license.

The regulatory foundation for this process is found in 29 CFR 1910.178(l)(1), which states: "The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by the successful completion of the training and evaluation specified in this paragraph (l)."

1.1 The Mandatory Three-Part Training Protocol

To achieve full compliance, the operator training program must rigorously adhere to the three distinct phases outlined by OSHA. Completion of one phase without the others renders the operator non-certified and the employer liable for non-compliance penalties.

Formal Instruction (Theoretical): Classroom learning covering safety principles, truck mechanics, and regulations.

Practical Training (Hands-on): Demonstrations and supervised driving exercises.

Performance Evaluation (Certification): A final, in-person assessment of competency in the actual workplace.

1.2 Minimum Requirements and Prerequisites

Before training commences, two basic requirements must be met:

Age Restriction: The operator must be at least 18 years of age to operate any powered industrial truck (non-agricultural).

Physical Capability: The operator must be physically capable of safely performing the job duties, including the ability to lift, sit, stand, and maintain spatial awareness.

2. Phase I: Formal Instruction (Theoretical Training)

The formal instruction phase imparts the foundational, truck-related, and general knowledge necessary for safe operation. This phase can be delivered via lectures, discussion, video, or, most conveniently, interactive online training platforms.

2.1 Required Truck-Related Topics (29 CFR 1910.178(l)(3)(i))

The theoretical training must cover the general principles of safe PIT operation, including, but not limited to:

Vehicle Controls: Location and function of all controls and instrumentation.

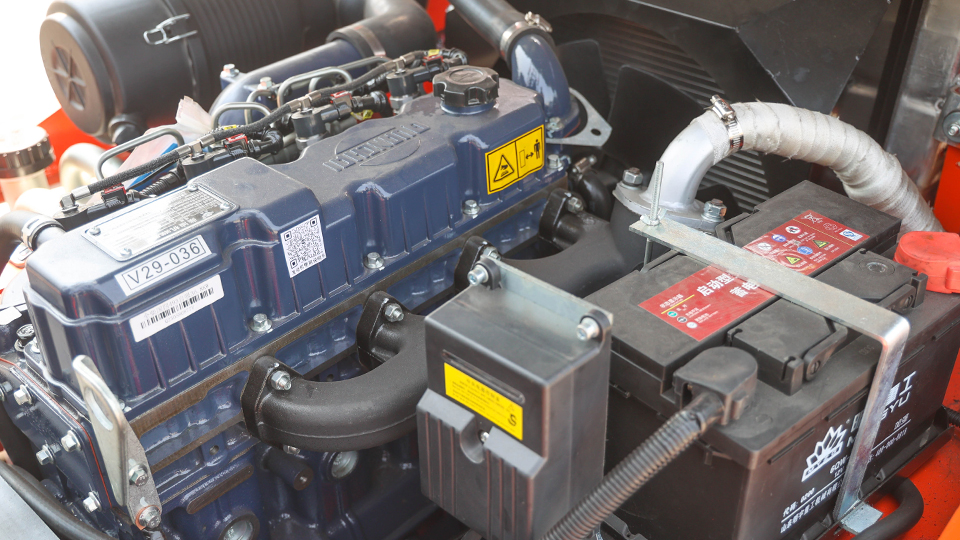

Engine/Motor Operation: Specifics of the power source (electric, LP-Gas, diesel, gasoline) and safe refueling/recharging procedures.

Steering and Maneuvering: Understanding the difference between rear-wheel and front-wheel steering and the risk of the Stability Triangle principle.

Stability and Capacity: The critical relationship between load center, load capacity, and the risk of tip-over (lateral and longitudinal stability).

Inspection and Maintenance: Procedures for performing mandatory daily pre-operation inspections and when to remove a truck from service.

Attachments: Limitations and operational changes required by non-standard forks or attachments (e.g., drum clamps, push-pull).

3. Phase II and III: Practical Training and Performance Evaluation

The critical differentiator between simple "training" and full "certification" lies in the completion of these two on-site, employer-controlled phases.

3.1 The Role of the "Qualified Trainer/Evaluator"

Practical training and evaluation must be conducted by a "qualified person," defined by OSHA as one who, "by virtue of knowledge, training, and experience, can effectively train powered industrial truck operators and evaluate their competence" (29 CFR 1910.178(l)(2)(iii)). This person must possess the practical skills to operate the specific equipment safely under the conditions prevailing in the employer's workplace. Many companies utilize internal staff who have completed a Train-the-Trainer course to establish this internal compliance capability.

3.2 Practical Training: Site-Specific Mandates (29 CFR 1910.178(l)(3)(ii))

The hands-on training and practice must be tailored to the specific working environment, covering site-specific hazards that cannot be taught in a generic online course. Required workplace-related topics include:

Surface Conditions: Operating on ramps, grades, wet/slippery floors, and poor surface conditions specific to the facility.

Traffic Management: Protocols for areas with pedestrian traffic, blind spots, and intersections; use of horns and warning devices.

Load Handling: Safe manipulation, stacking, and unstacking procedures for the type of materials handled (e.g., cartons, steel coils, lumber).

Restricted Areas: Operating safely in narrow aisles, elevators, hazardous (classified) locations, and near overhead obstacles.

Loading Docks: Procedures for safe truck and trailer entry/exit, the use of wheel chocks, and securing dock plates.

3.3 The Final Performance Evaluation (The Certification Act)

The final step in the process is the formal evaluation. The qualified person must observe the operator performing the job tasks and formally assess their competency to operate the equipment safely and efficiently. This evaluation must be documented and must include demonstration of skills such as:

Starting, stopping, and steering control.

Maneuvering in reverse and around corners.

Proper load centering and weight capacity adherence.

Safe loading/unloading of racking and trailers.

Only upon successful completion of this final evaluation is the employee considered OSHA Certified.

4. Documentation, Validity, and Refresher Training

OSHA mandates strict documentation and periodic checks to ensure continuous compliance.

4.1 Certification Documentation Requirements (29 CFR 1910.178(l)(6))

The employer must prepare a written certification record for each successful operator. This record must be retained and include:

Name of the operator.

Date of the training.

Date of the evaluation.

Name(s) of the person(s) performing the training or evaluation.

This document is the employer's official declaration of competency.

4.2 The Triennial Evaluation and Refresher Training (29 CFR 1910.178(l)(4))

OSHA requires that the operator’s performance be evaluated at least once every three years (36 months). This triennial evaluation ensures that unsafe habits have not developed. Refresher training (covering both formal and practical components) is mandatory before the three-year period if any of the following occur:

The operator is involved in an accident or a near-miss incident.

The operator is observed operating the PIT in an unsafe manner.

The operator is assigned to operate a different type of truck (different classification).

Conditions in the workplace change in a manner that could affect safe operation.

The triennial performance evaluation reveals a need for remediation.

5. Technical Specification: The 7 Classes of Powered Industrial Trucks

A technical understanding of the seven PIT classifications is essential, as certification is class-specific. An operator certified on a Class IV (Internal Combustion Cushion Tire) counterbalance truck is not automatically certified to operate a Class II (Electric Motor Narrow Aisle) reach truck.

OSHA Class Type of Truck Power Source Common Application

Class I Electric Motor Rider Electric General warehouse, manufacturing

Class II Electric Motor Narrow Aisle Electric High-density storage, reach trucks

Class III Electric Motor Hand or Hand/Rider Electric Pallet jacks, stackers

Class IV Internal Combustion Engine (Cushion) LP-Gas, Gas, Diesel Dry, indoor surfaces (warehouse)

Class V Internal Combustion Engine (Pneumatic) LP-Gas, Gas, Diesel Rough terrain, lumber, outdoor yards

Class VI Electric and Internal Combustion Tractors Electric/IC Towing, baggage handling

Class VII Rough Terrain Forklift Trucks Diesel, Gas Construction, logging, outdoor sites

(The full 2000-word article would continue with a detailed analysis of the stability triangle, advanced load handling techniques, the process of running a 'Train-the-Trainer' program, and a deeper dive into common OSHA citations and penalty structures related to 29 CFR 1910.178.)

Structure for the remaining ~1300 words:

6. Engineering Principles and Stability Dynamics

6.1 The Stability Triangle: Detailed technical explanation of the geometric stability principle for counterbalance trucks.

6.2 Load Center Calculation: How the load center distance affects residual capacity and mast stability.

6.3 Tip-Over Analysis: Longitudinal (forward/backward) and Lateral (side) stability factors and how operational errors violate stability limits.

7. Developing an OSHA-Compliant Training Program (Employer’s Guide)

7.1 Trainer Competency: In-depth look at the "knowledge, training, and experience" requirement for the Qualified Person. The process of using Train-the-Trainer courses.

7.2 Curriculum Development: Checklist for customizing the mandatory Truck-Related and Workplace-Related topics into a single, cohesive training manual.

7.3 Evaluation Metrics: Creating objective, measurable criteria for the final performance test (e.g., stacking precision, aisle clearance, stopping distance under load).

8. Financial and Legal Consequences of Non-Compliance

8.1 OSHA Penalty Structure: Detailed table/explanation of current maximum fines for Serious, Other-Than-Serious, and Willful/Repeated violations of 29 CFR 1910.178(l).

8.2 Liability and Insurance: The impact of untrained operators on workers’ compensation, insurance premiums, and tort liability in the event of a catastrophic accident.

9. Special Topic: Hazardous Location and Vehicle Designation

9.1 OSHA 1910.178(c) and (d): Technical requirements for using specially designated trucks (e.g., EX, EE, ES) in classified hazardous areas (flammable vapors, dusts).

9.2 Vehicle Modification Rules: Mandates against unauthorized modification and the requirement for manufacturer re-rating (1910.178(a)(4)).

10. Conclusion: Certification as Risk Mitigation

Final summary of the three mandatory steps and the employer's ultimate role.

Reinforcement of certification as an ongoing, continuous safety program, not a one-time event.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China