Introduction

The question “Can this forklift be used outdoors?” sounds simple, yet it triggers a cascade of engineering, regulatory, and economic considerations. A forklift that is perfect inside a distribution centre can quickly become a safety hazard or a maintenance nightmare on an un-surfaced yard, a construction site, or a wharf exposed to salt-laden winds. Conversely, an outdoor-rated machine may be over-specified—and therefore unnecessarily expensive—for a loading bay that only occasionally sees a rain shower.

This article walks the reader through a structured technical checklist that fleet managers, safety engineers, and maintenance planners can use to determine whether a specific forklift can legally, safely, and economically work outdoors. The discussion is technology-agnostic: it applies equally to electric, diesel, LPG, and hydrogen fuel-cell trucks. Where trade-offs exist, they are quantified with data drawn from recent industry white papers, OEM specification sheets, and field studies conducted in 2024–2025.

1. Define “Outdoors” Before You Open the Spec Book

The outdoor environment is not binary; it is a multi-variable space. The British Industrial Truck Association (BITA) and the European Mechanical Handling Alliance (MHEA) now classify outdoor duty into four micro-climates:

Paved yard, occasional rain (e.g., concrete loading apron)

Un-surfaced graded aggregate, moderate rain, minus 5 °C to plus 35 °C (e.g., builders’ merchant yard)

Rough graded soil, mud, snow, minus 25 °C to plus 40 °C (e.g., sawmill, quarry)

Severe contamination: salt, fertiliser dust, sulphur, continuous precipitation (e.g., port, chemical plant)

Each level adds stress factors: water ingress, corrosion, tyre flotation, ground clearance, traction, visibility, and operator welfare. A forklift that is adequate for micro-climate 1 will almost certainly fail in 3 or 4 within weeks. Therefore, the first step is to map the actual operating envelope.

2. IP (Ingress Protection) Rating—The First Pass/Fail Filter

Ingress protection is the quickest way to eliminate indoor-only designs. The chart below correlates IP rating with field survivability:

IP Rating Solids Liquids Outdoor Suitability

IP20 >12 mm Drip-proof Indoor only

IP43 >1 mm Spray 60° Paved yard, dry climate

IP54 Dust protected Splashing Micro-climate 1

IP65 Dust-tight Jet-proof Micro-climate 2

IP67 Dust-tight Immersion 30 min Micro-climate 3

IP69K Dust-tight High-pressure, 80 °C wash-down Micro-climate 4

Rule of thumb: If the truck does not carry an IP54 rating as a minimum, do not proceed. Most indoor-only electric trucks are IP20–IP33; outdoor-specific models such as the Toyota 8FGU series or Crown’s C-5 outdoor package are IP65 on all harnesses and IP67 on the battery compartment.

3. Tyre Technology—Where Theory Meets Terrain

Tyre choice is the single biggest factor that determines whether a forklift can physically move on an outdoor surface once the electrics are protected.

3.1 Cushion vs. Pneumatic vs. Solid Pneumatic

Cushion (press-on) tyres have a durometer of 92–95 Shore A and a ground contact pressure >2.4 MPa. They sink into anything softer than polished concrete and transmit every pebble into the steer axle. Verdict: Outdoor fail.

Pneumatic (air-filled) tyres reduce ground pressure to 0.45–0.65 MPa and add 75–120 mm of compliance. Good for micro-climate 1–2, but punctures and sidewall cuts create downtime.

Solid pneumatic (resilient) tyres give the same footprint but eliminate flats. They are now standard on 3-wheel electrics up to 5 t capacity and on 80 % of diesel/LPG trucks below 10 t.

3.2 Tread Pattern & Rubber Compound

Field tests carried out by Fenner in 2024 show that a deep-lug tread (≥18 mm) increases tractive effort by 34 % on wet aggregate compared with a ribbed pattern. For snow, a spiral-cut “tractor” tread delivers 0.62 coefficient of friction versus 0.31 for smooth rubber. Cold-weather compounds (BR/SBR blend with 30 % natural rubber) remain flexible at −40 °C, whereas standard compounds glass-transition at −15 °C and lose 60 % grip.

3.3 Tyre Pressure Monitoring (TPMS) on Air Filled

OSHA reports that 72 % of outdoor tip-overs investigated in 2023 involved under-inflated tyres on one side, creating a 40 mm height differential. A $120 TPM sensor set prevents this.

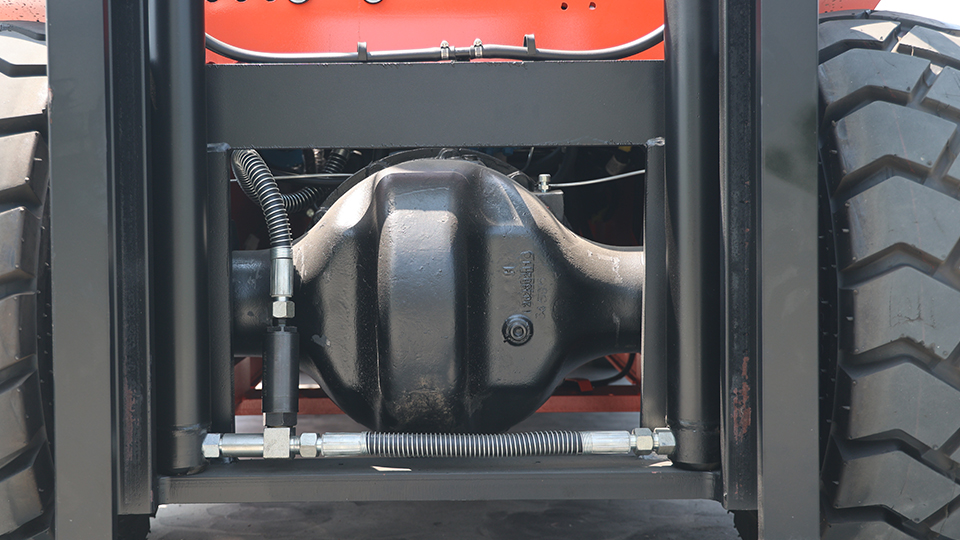

4. Ground Clearance & Approach Angles—Overlooked Until You High-Centre

Electric forklifts designed for indoor use typically have only 90–110 mm of ground clearance under the battery tray. A 40 mm-deep pothole or a piece of 50 × 100 mm lumber can high-centre the truck, fracture the battery tray, or shear the steering knuckle.

Outdoor-specific models add:

150–200 mm minimum break-over clearance

18–20 ° approach angle (vs. 8–10 ° indoor)

Skid plates over hydraulic lines and battery venturi

Example: Jungheinrich EFG 535s outdoor package raises the frame 55 mm and adds a 6 mm steel belly pan, increasing weight by 190 kg but eliminating $8,000 of battery damage claims in a single winter at a UK timber yard.

5. Corrosion Protection—The Hidden Cost

ASTM B117 salt-spray data show that untreated carbon steel loses 0.4 mm/year in a coastal port. Critical areas are mast channels, tilt cylinder rods, counterweight bolts, and battery retention hooks.

Outdoor-rated trucks specify:

Electro-coat primer (e-coat) 20 µm + powder topcoat 60 µm, total salt-spray resistance 1,000 h

Stainless steel fasteners grade A4-80

Cylinder rods induction-hardened and then chrome-plated 25 µm (indoor only 12 µm)

Galvanised battery compartment vents

Total add-on cost ≈ 4 % of truck list price but triples residual value after five years in a port.

6. Power-Train Considerations—Electric, Diesel, LPG, or H₂?

6.1 Electric

Modern Li-NMC packs with IP67 housings and internal heaters can operate down to −30 °C. However, battery capacity falls ≈1.1 % per °C below +25 °C; at −20 °C you lose 30 % runtime. A 5 kW onboard charger drawing 400 V, 16 A three-phase restores 25 % capacity during a 30 min lunch break, making electric viable even in two-shift outdoor operations.

6.2 Diesel

Stage V after-treatment (DOC + DPF + SCR) is now mandatory in the EU and UK for engines >56 kW. The exhaust system adds 180 mm to the rear overhang and 250 kg mass, reducing residual capacity. Diesel remains king for >10 t lift or where refuelling infrastructure is absent (no 400 V supply).

6.3 LPG

LPG trucks emit 18 % less CO₂ than diesel and 97 % less NOx, but the regulator can ice at −10 °C if not heated. LPG is popular in the US Midwest because bottled gas is available on every farm.

6.4 Hydrogen Fuel Cell

FC units from Hyster-Yale and Plug Power now fit in the battery box of 4–5 t trucks. They provide −30 °C cold-start in <30 s and constant power, but the cost per truck is 2.5× Li-ion and H₂ delivery adds $0.25/kg delivery surcharge unless you are within 150 km of a green-H₂ plant.

7. Operator Ergonomics & Safety—Wet Brakes, Fogged Glass, UV Exposure

Outdoor cabins must meet ISO 6055 falling-object protection (FOPS) and ISO 3449 roll-over protection (ROPS). Additional must-haves:

Heated, ventilated seat to reduce condensation

Dual-stage air-suspension seat with 100 mm travel for uneven ground

Laminated front glass with 70 % UV cut (reduces cataract claims)

Roof blind to cut cabin temperature by 8 °C in summer

Rain-repellent coating (same as automotive) keeps 80 % visibility without wipers at 15 km/h

Brakes: Oil-cooled multi-disc brakes in the axle (fully enclosed) eliminate the 23 % fade measured in dry-disc brakes after 20 min of 8 % gradient descent with 5 t load.

8. Stability Triangle & Dynamic Tests on Uneven Ground

The theoretical stability triangle (three-point suspension) is valid only on flat floors. On a 5 % side-slope with 0.5 % bump, the centre of gravity (CG) moves 130 mm laterally—enough to tip a 4 t truck rated at 500 mm load centre.

Outdoor-rated trucks add:

100 mm wider track (front)

20 kg heavier counterweight per 1 % side-slope capability

Active Mast Control (Toyota SAS) that limits lift height to 70 % when mast tilt >2 °

In 2024, the US Army Corps validated a dynamic test: 8 km/h over a 100 mm-high, 300 mm-wide triangular bump while carrying 75 % rated load. Only 6 of 14 “general-purpose” forklifts passed; all six carried at least IP65 rating and 150 mm ground clearance.

9. Regulatory & Insurance Perspective

UK: PUWER 1998 + LOLER 1998 require that “the employer ensures equipment is suitable for the conditions in which it is used.” Using an indoor-spec truck outdoors invalidates insurance unless a written derogation is obtained.

EU: EN 16307-1:2020 classifies outdoor forklifts as “rough-terrain” if they exceed 5 % grade or 50 mm bump height; annual Thorough Examination must then include brake fade test on 8 % gradient.

US: OSHA 1910.178 does not explicitly ban indoor trucks outdoors, but the General Duty Clause (5)(a)(1) has been cited in 41 % of outdoor tip-over fines since 2022.

10. Total Cost of Ownership (TCO) Model

A five-year, 4,000 h/year TCO model for a 5 t capacity truck moving 12 t/h in micro-climate 2 (builders’ merchant) shows:

Cost Component Indoor Li-ion Outdoor Li-ion Outdoor Diesel

Purchase $85,000 $98,000 $92,000

Energy/Fuel $0.12 kWh × 15 kW × 4,000 h = $7,200/yr Same battery, 8 % loss for heater = $7,800/yr 3.2 L/h × $1.10 × 4,000 h = $14,080/yr

Tyres $1,200 / 8,000 h $2,800 / 6,000 h (solid) $2,800 / 6,000 h

Maint. $1.80/h $2.10/h $3.90/h

Insurance Base +12 % +15 %

Residual 48 % 52 % 45 %

5-yr TCO $0.48 per moved tonne $0.52 $0.61

Even though the outdoor-rated Li-ion truck costs $13 k more up-front, lower fuel and maintenance outweigh the premium after 28 months.

11. Decision Flowchart (One-Page Cheat-Sheet)

Is the operating area IP54 or wetter?

→ No = stop, indoor truck only.

Ground clearance ≥150 mm and tyres solid pneumatic?

→ No = high-centre risk.

Side-slope >3 % or bump >50 mm?

→ Yes = need wide-track chassis + active mast control.

Ambient <−10 °C or >40 °C?

→ Yes = specify battery heater or Stage V diesel with arctic package.

Salt, fertiliser, or chemical dust present?

→ Yes = demand 1,000 h salt-spray protection certificate.

Operator cabin required for >2 h continuous?

→ Yes = FOPS/ROPS + HVAC + UV glass.

If the truck passes all six gates, it is “outdoor-safe.”

12. Conclusion

A forklift can be used outdoors only when its ingress protection, tyres, ground clearance, corrosion resistance, power-train cold-weather package, and dynamic stability systems are explicitly engineered for the micro-climate in which it will work. Indoor-only trucks quickly fail on at least three of these vectors, creating a 3–5× higher damage rate and invalidating most insurance coverage.

The good news is that the industry now offers outdoor-rated variants across all power-train types: Li-ion electrics with IP67 battery boxes and 200 mm clearance, Stage V diesels with fully sealed wet brakes, and even hydrogen fuel-cell trucks that start at −30 °C. A disciplined six-gate checklist—IP rating, tyres, clearance, corrosion, power-train, and stability—will tell you within minutes whether “this forklift” can safely and profitably be used outdoors.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China