Product Description

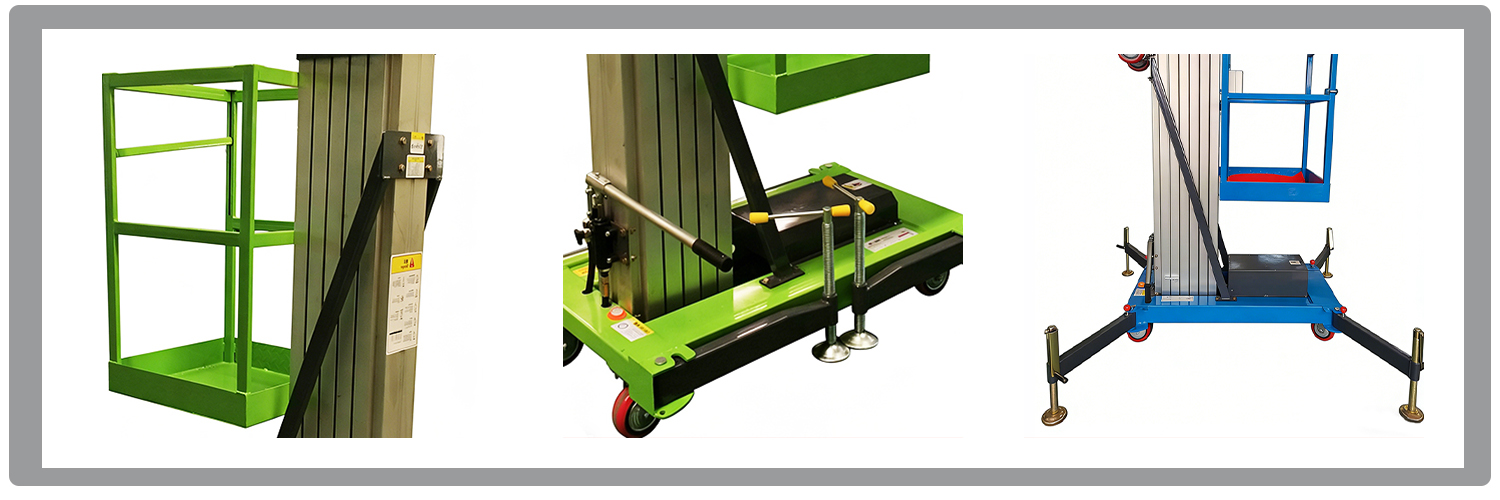

ZG-DZ-10SD is a lightweight and highly maneuverable single-mast aluminum alloy lift, designed for high-altitude operations in narrow spaces. The equipment adopts a high-strength aluminum alloy main beam (200×95×2000mm specification), balancing structural strength and weight control (net weight approx. 340kg). With a maximum platform working height of 11.7m and a platform height of 9.8m, combined with a 0.6×0.6m working platform, it can carry 117kg of heavy objects or support single-person efficient operations. The compact body (overall dimensions 1.36×0.90×2.1m) is equipped with 150mm diameter wheels and outrigger structures, allowing flexible passage through narrow aisles and stable support during operations, adapting to multi-scenario high-altitude operation needs.

Advantages

Lightweight & Flexible: Aluminum alloy material + compact body, can easily pass through narrow passages within 1m, and can be pushed and transferred by a single person, greatly reducing labor costs.

Safe & Stable: Equipped with outrigger structures (outrigger length 770mm), which can support stably during operation; the platform adopts 3mm flat plate + guardrail design, balancing load-bearing and safety protection.

Durable: The main beam is made of high-strength aluminum alloy, the base frame is made of 50×100×3.5mm square tube, and key components (such as LH0834 leaf chain) are made of industrial-grade materials, extending the service life of the equipment.

Easy to Operate: The lifting process is simple and easy to learn, and can be mastered quickly without professional training; the platform size is suitable for single-person operation, with comfortable operating space and wide field of vision.

Detailed Parameters

Rated Load

117kg

Net Weight

Approx. 340kg

Maximum Platform Working Height

11.7m

Maximum Platform Height

9.8m

Platform Length

0.60m

Platform Width

0.60m

Overall Dimensions

1.36×0.90×2.1m

Main Beam Material

High-strength Aluminum Alloy (200×95×2000mm)

Platform Surface Material

3mm Flat Plate

Platform Rectangular Tube

30×30×2.5mm

Single Outrigger Length

770mm

Base Frame

50×100×3.5mm Square Tube

Base Plate

3mm Flat Plate

Outrigger Material

40×80×3mm Rectangular Tube

Cylinder

Outer Diameter: 50mm / Inner Diameter: 40mm; Height: 1900mm (1 Piece)

Wheel Size

150mm

Chain

Leaf Chain LH0834

Service Guarantee

Warranty Service: The main structure (aluminum alloy main beam, base frame) enjoys a 1-year warranty, and core components (cylinder, chain) enjoy a 6-month warranty. Free repair is provided for non-human damage.

Technical Support: 24/7 multi-channel consultation (WhatsApp/Skype/WeChat) is available, supporting remote assistance such as installation guidance and troubleshooting.

Spare Parts Supply: Long-term supply of original spare parts (such as wheel sets, outrigger components) with fast delivery after ordering, reducing equipment downtime.

Customization Service: According to operation needs, different specifications of platform extensions or protective accessories can be adapted to meet personalized scenario requirements.

Applicable Scenarios

Commercial Scenarios: Shopping mall ceiling maintenance, office building air conditioning installation, hotel exterior wall cleaning, exhibition stage construction, etc.

Industrial Scenarios: Narrow-space high-altitude operations such as factory pipeline laying, warehouse shelf maintenance, and equipment inspection.

Municipal Scenarios: Outdoor flexible operations such as street lamp maintenance, traffic sign installation, and urban greening pruning.

Other Scenarios: Single-person high-altitude operation scenarios such as villa decoration, park facility maintenance, and wall decoration in small construction projects.

About us

MYZG has 12 modern production workshops, with an annual production capacity of 80,000 units per workshop,more than 200 large and medium-sized advanced level equipment.We have advanced scientific research test facilities, intelligent inspection system.Automated and intelligent production, in order to build an industry digital factory.The whole production process is controlled by ERP system,MYZG machines are of excellent quality because we have very strict quality supervision and control.

MYZG machines are exported all over the world,about more than 130 countries.We use brand engine, the matching parts of the machine are easy to get

MYZG have perfect after-sales service,and provide one year warranty .Our price is more competitive and the good service well received by customers.

Every machine produced by Mingyu has to undergo several rigorous tests, and it can be finally delivered to customers only after all tests are completed and qualified.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China