That's a great question! While both forklifts and pallet jacks are used to move palletized loads, they have distinct differences in their capabilities, operation, and applications. Here's a breakdown of the key distinctions:

Forklift:

Lifting Mechanism: Forklifts use a powered hydraulic system to raise and lower a pair of forks. They have a mast that allows them to lift loads to significant heights, often several feet.

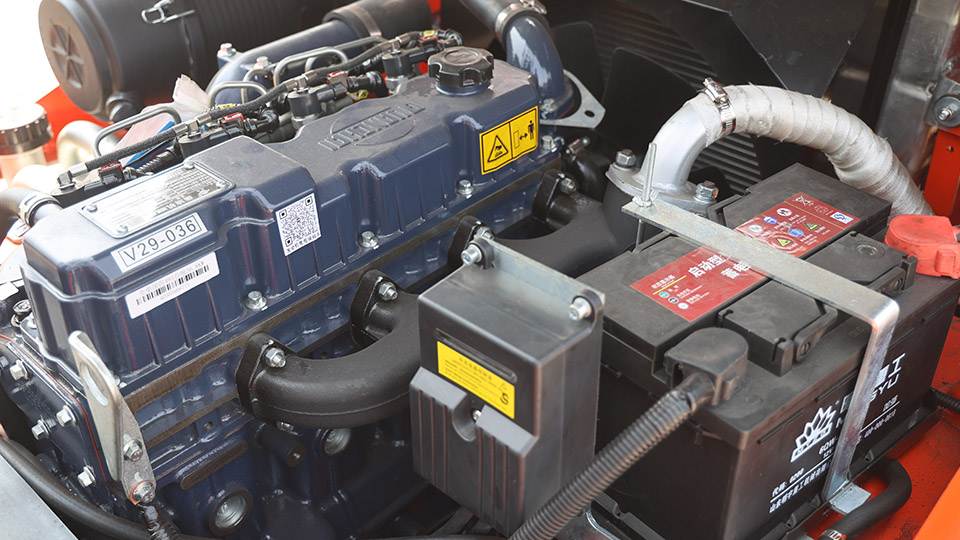

Power Source: Forklifts are typically powered by electric batteries, internal combustion engines (propane, diesel, gasoline), or a combination of both.

Operation: Forklifts are operated by a trained driver who sits or stands within the machine and uses controls for steering, lifting, tilting the mast, and moving the forks. They have more complex controls and require specific training and certification to operate safely.

Maneuverability: While some forklifts are designed for tight spaces, they generally require more room to maneuver compared to pallet jacks due to their larger size and turning radius.

Load Capacity: Forklifts are designed to lift and transport much heavier loads than pallet jacks, ranging from a few thousand pounds to tens of thousands of pounds.

Versatility: Forklifts are highly versatile and can perform a wider range of tasks, including stacking goods on high shelves, loading and unloading trucks, and transporting materials over longer distances and sometimes rougher terrain (depending on the type of forklift).

Cost: Forklifts have a significantly higher purchase price, as well as higher maintenance and operational costs (fuel/electricity, more complex repairs).

Portability: Forklifts are generally not easily portable between different locations without specialized trailers due to their weight and size, although some compact or "portable" forklifts exist for easier transport.

Operator Fatigue: Forklifts reduce operator fatigue due to powered lifting and movement, and some even have rider platforms or seats.

Pallet Jack:

Lifting Mechanism: Pallet jacks (also called pallet trucks, hand trucks, or pump trucks) use a simple hydraulic pump system, usually hand-operated (though electric versions exist), to lift pallets a few inches off the ground for horizontal movement. The lifting height is very limited, typically only 3 to 8 inches.

Power Source: Manual pallet jacks are powered by human effort to pump the hydraulic system and move the load. Powered pallet jacks use electric motors for lifting and sometimes for propulsion.

Operation: Manual pallet jacks are operated by a person who uses a handle to pump the jack and steer the load. Electric pallet jacks have controls on the handle for powered lifting and movement. They are generally simpler to operate than forklifts, but powered versions may still require some training.

Maneuverability: Pallet jacks are very maneuverable, especially manual ones, and are excellent for navigating tight spaces like narrow aisles in warehouses, inside truck trailers, and retail environments.

Load Capacity: Pallet jacks have a lower load capacity compared to forklifts, typically handling loads up to around 5,500 pounds for standard models.

Versatility: Pallet jacks are primarily designed for horizontal movement of palletized loads over short distances on relatively flat surfaces. They are not designed for stacking or lifting to significant heights.

Cost: Pallet jacks have a much lower purchase price and significantly lower maintenance and operational costs compared to forklifts.

Portability: Manual pallet jacks are relatively lightweight and portable and can be easily moved between different areas or even transported in the back of a truck. Electric pallet jacks are heavier but still more portable than most forklifts.

Operator Fatigue: Manual pallet jacks can lead to operator fatigue, especially when moving heavy loads or over long distances. Electric pallet jacks reduce this fatigue.

Here's a table summarizing the key differences:

Feature Forklift Pallet Jack

Lifting Height High (several feet) Low (a few inches)

Power Source Electric, Internal Combustion Manual hydraulic, Electric hydraulic

Operation Trained operator, complex controls Operator pushing/pulling, simpler controls

Maneuverability Good, but generally requires more space Excellent, ideal for tight spaces

Load Capacity High (thousands to tens of thousands of lbs) Lower (up to around 5,500 lbs for standard)

Versatility High (lifting, stacking, transporting) Primarily horizontal transport

Cost High (purchase, maintenance, operation) Low (purchase, maintenance, operation)

Portability Generally low Relatively high (especially manual)

Operator Fatigue Low (powered operation) Can be high (manual), low (electric)

In essence, forklifts are for lifting and moving heavy loads to significant heights and over longer distances, while pallet jacks are for the simple horizontal movement of palletized loads over short distances. The choice between the two depends entirely on the specific material handling needs of the operation.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China