Abstract

The 5-ton hand pallet truck represents a robust solution in manual material handling, offering significantly higher load capacities than standard models. While indispensable for moving exceptionally heavy loads in warehouses, manufacturing plants, and distribution centers, their price can vary considerably. This article provides a comprehensive technical overview of the factors influencing the cost of a 5-ton hand pallet truck, delves into key specifications that impact pricing, and offers guidance on how to assess value beyond the initial purchase price. We will explore the components contributing to the overall cost, the distinctions between basic and advanced models, and crucial considerations for potential buyers to ensure they invest in equipment that meets their operational needs and budget.

1. Introduction

The hand pallet truck, or pallet jack, is a fundamental piece of equipment in virtually any industry that handles goods on pallets. While the most common models are designed for loads between 2 and 3 tons (4,400 to 6,600 lbs), the demand for heavier lifting capabilities has led to the development of specialized high-capacity units, prominently including the 5-ton (10,000 lbs) hand pallet truck. These heavy-duty versions are engineered for resilience and strength, capable of moving substantial weights that would overwhelm standard pallet jacks. However, this increased capability comes with a corresponding increase in complexity and material quality, which directly impacts their market price. Understanding the nuances of what drives these costs is essential for informed purchasing decisions.

2. Understanding the "5-Ton" Specification

A "5-ton" hand pallet truck signifies a nominal lifting capacity of 5 metric tons, which equates to approximately 11,023 pounds or, more commonly in North America, 10,000 pounds when referring to a "5-ton" capacity (using the short ton equivalent). This is a substantial capacity, requiring significant structural reinforcement and a more robust hydraulic system compared to standard models.

2.1. Why 5 Tons? Typical Applications

Five-ton hand pallet trucks are typically found in environments where very heavy loads are common, such as:

Industrial Manufacturing: Moving heavy machinery components, raw materials (e.g., steel coils, large castings).

Heavy Equipment Dealerships: Relocating large parts or components.

Building Materials Suppliers: Transporting dense materials like concrete blocks, large tile crates, or bags of cement.

Distribution Centers: Handling exceptionally heavy consolidated shipments.

Specialized Warehousing: For industries dealing with extremely dense or large products.

3. Key Factors Influencing the Price of a 5-Ton Hand Pallet Truck

The price of a 5-ton hand pallet truck is not a fixed figure. It is a dynamic value influenced by several critical technical and commercial considerations.

3.1. Build Quality and Material Specifications

This is perhaps the most significant determinant of cost.

Steel Gauge and Type: High-capacity pallet trucks require thicker, higher-grade steel for the chassis, forks, and lifting linkages to prevent bending or structural failure under heavy loads. High-tensile strength steel, often seen in premium models, costs more.

Welding Quality: Superior welding techniques and quality control contribute to structural integrity and thus, to the overall price.

Powder Coating/Finish: High-quality, durable powder coating protects against corrosion and wear, contributing to longevity and a higher price point.

Fork Reinforcement: 5-ton models often feature reinforced fork tips and extra support beams beneath the forks to prevent distortion.

3.2. Hydraulic System Robustness

The hydraulic pump is the heart of the lifting mechanism.

Pump Design: A 5-ton capacity demands a much more powerful and durable hydraulic pump than a standard 2-ton unit. This includes larger cylinder bores, stronger seals, and more robust valves.

Piston and Rod Material: Hardened chrome-plated pistons and high-quality seals are crucial for preventing leaks and ensuring smooth, reliable lifting under extreme pressure.

Overload Protection: Many premium 5-ton models include an overload relief valve, which prevents the operator from lifting loads beyond the rated capacity, protecting the hydraulic system and structure. This feature adds to the cost.

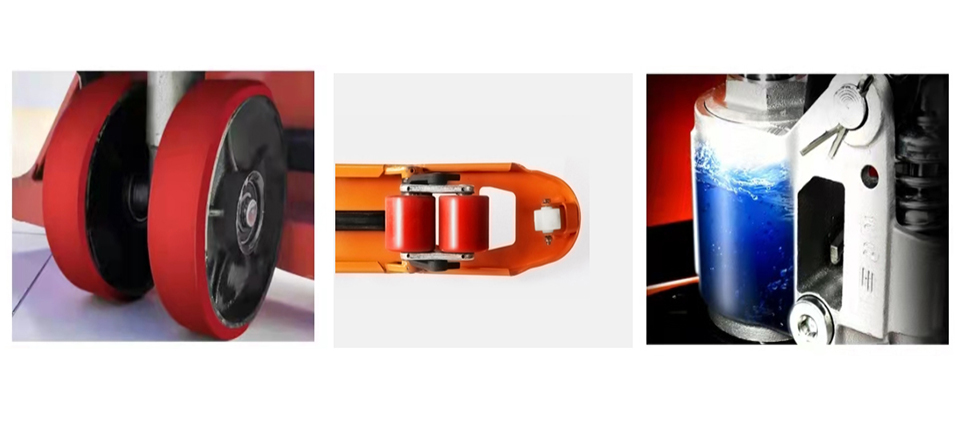

3.3. Wheel and Bearing Configuration

The ability to move 5 tons smoothly and safely depends heavily on the wheels.

Wheel Material: Options include nylon, polyurethane, and rubber.

Nylon: Hardest, lowest rolling resistance on smooth floors, but can be noisy and potentially damage sensitive floors. Generally the least expensive.

Polyurethane (PU): Good balance of durability, quiet operation, and floor protection. Often slightly more expensive than nylon.

Rubber: Quieter, best for uneven surfaces, but higher rolling resistance and quicker wear. More expensive.

For 5-ton capacities, heavy-duty polyurethane or steel wheels (sometimes with a rubber or PU tread) are common to withstand the immense pressure.

Number of Wheels: Most 5-ton models will feature tandem load wheels (four wheels per fork) to distribute the heavy weight more effectively, reducing point pressure on the floor and increasing stability. This adds to the cost compared to single-wheel configurations.

Bearings: High-quality sealed bearings (e.g., precision ball bearings) reduce rolling resistance and increase durability, especially under heavy loads, contributing to a higher price.

3.4. Handle Design and Ergonomics

While seemingly minor, the handle affects usability and cost.

Ergonomic Grip: Contoured handles with comfortable grips reduce operator fatigue.

Reinforced Handle Base: A 5-ton truck requires a much stronger handle pivot and linkage system to withstand the forces exerted during pumping and steering.

Control Mechanisms: High-quality, responsive lowering and lifting controls are important for safety and ease of use.

3.5. Manufacturer and Brand Reputation

Tier 1 Brands: Established manufacturers with a reputation for quality, durability, and extensive after-sales support (e.g., Raymond, Crown, Toyota (BT), Jungheinrich, Still, Big Joe) typically command higher prices. They invest heavily in R&D, material testing, and quality control.

Mid-Tier Brands: Offer a good balance of features and price.

Economy/Value Brands: Often produced in high volumes with basic features, focusing on competitive pricing. Quality and longevity can vary.

Warranty and Support: A longer warranty period and readily available spare parts and service networks will also influence the price.

3.6. Additional Features and Customizations

Certain features can significantly increase the price:

Built-in Weigh Scale: Integrating a scale to weigh pallets directly on the truck adds considerable cost but provides immediate weight data, crucial for shipping or inventory.

Low Profile Forks: For specialized ultra-low pallets, requiring finer tolerances and stronger materials for thinner forks.

Stainless Steel/Galvanized Construction: Essential for corrosive, wet, or hygienic environments (e.g., food processing, pharmaceuticals). These materials are far more expensive than standard steel.

Quick-Lift Pump: Allows the forks to reach the pallet faster with fewer pumps when unloaded or lightly loaded, improving efficiency.

Brake Systems: Some heavy-duty manual pallet trucks can include a foot brake or hand brake for added safety on inclines or during loading/unloading, which adds to the cost.

Specific Fork Lengths/Widths: While standard sizes exist, customized fork dimensions for unusual pallet sizes will incur extra costs.

4. General Price Range (Historical & Influencing Factors)

Based on general market observations prior to my last update, a new, good-quality 5-ton hand pallet truck typically falls into the following broad price ranges. It is crucial to verify current market prices from multiple suppliers as these are estimates and subject to change.

Entry-Level / Basic Models (New):

Often from lesser-known brands or those focusing purely on the "5-ton" capacity without many advanced features.

Estimated Price Range: $700 - $1,200 USD

These models will likely have standard components, perhaps nylon wheels, and fewer ergonomic enhancements. They are designed for straightforward heavy lifting without significant bells and whistles.

Mid-Range / Good Quality Models (New):

From reputable mid-tier manufacturers, offering better build quality, more durable hydraulic systems, and potentially polyurethane tandem wheels.

Estimated Price Range: $1,200 - $2,500 USD

These are often the sweet spot for many businesses, balancing cost with reliability and a good feature set.

Premium / High-End Models (New):

From top-tier global brands, featuring superior materials, advanced hydraulic systems with overload protection, ergonomic handles, high-quality sealed bearings, and potentially options for specialized finishes (e.g., galvanized).

Estimated Price Range: $2,500 - $4,000+ USD

Models with integrated scales or full stainless steel construction would push prices significantly higher, potentially reaching $5,000 - $10,000+ USD for specialized versions.

4.1. Used Pallet Trucks

Purchasing a used 5-ton hand pallet truck can significantly reduce the cost, often by 30-60% or more, depending on age, condition, and remaining service life. However, caution is advised:

Inspection: Thoroughly inspect the hydraulic system for leaks, check for bent forks, worn wheels, and handle integrity.

Repairs: Factor in potential repair costs if components need replacing.

No Warranty: Used equipment often comes with limited or no warranty.

5. Beyond the Initial Purchase Price: Total Cost of Ownership (TCO)

When evaluating the price of a 5-ton hand pallet truck, it's critical to consider the Total Cost of Ownership (TCO), not just the upfront purchase price.

5.1. Durability and Longevity

A cheaper pallet truck might require more frequent repairs or replacement, leading to higher long-term costs. Investing in a higher-quality unit often translates to a longer operational life and less downtime.

5.2. Maintenance and Spare Parts Availability

Parts Cost: Some proprietary parts from premium brands might be more expensive, but they are generally more readily available.

Ease of Maintenance: Well-designed units are easier to service, reducing labor costs for repairs.

5.3. Operator Productivity and Ergonomics

An ergonomically designed handle and a smooth, easy-to-pump hydraulic system can significantly reduce operator fatigue, especially when moving 5 tons repeatedly. This translates to higher productivity and fewer injury claims.

5.4. Safety Features

Features like overload protection, robust steering, and reliable wheel brakes contribute to a safer working environment, reducing the risk of accidents and associated costs (medical bills, insurance premiums, lost productivity).

5.5. Resale Value

Higher-quality brands often retain a better resale value, which can be a factor if you plan to upgrade or replace equipment periodically.

6. Where to Buy and How to Get the Best Price

Industrial Equipment Suppliers: Specialized material handling dealers are the primary source. They often offer a range of brands, service, and spare parts.

Online Retailers: Large e-commerce platforms specializing in industrial equipment often carry a wide selection, sometimes at competitive prices.

Manufacturer Websites: Directly from the manufacturer or their authorized distributors.

Auctions and Used Equipment Dealers: For second-hand options.

Tips for Getting the Best Price:

Get Multiple Quotes: Always solicit quotes from at least 3-5 different suppliers.

Negotiate: Don't be afraid to negotiate, especially if purchasing multiple units.

Ask About Discounts: Inquire about volume discounts, seasonal promotions, or end-of-quarter deals.

Clarify Warranty and Support: Understand what is included in the price regarding warranty, delivery, and initial setup.

Check Reviews: Read reviews from other users about the brand and specific model.

7. Conclusion

The price of a 5-ton hand pallet truck is a reflection of its formidable capacity, robust construction, and specialized components. While entry-level models might be available for under $1,000, high-quality, feature-rich, or specialized units can easily exceed $3,000, and even $10,000 for highly specialized versions. Buyers must look beyond the initial sticker price and consider the long-term value, durability, maintenance costs, and safety features. Investing in a well-built 5-ton hand pallet truck from a reputable manufacturer will not only provide the necessary lifting power but also ensure reliability, operator safety, and a lower total cost of ownership over its service life, making it a truly valuable asset in any heavy-duty material handling operation. Current market research is essential to obtain precise and up-to-date pricing information for specific models and features.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China