How to Transport a Forklift Truck: A Comprehensive Guide

Transporting a forklift truck is a task that, at first glance, may seem straightforward. However, it is a complex operation fraught with significant safety, legal, and logistical challenges. The sheer weight, unconventional dimensions, and high center of gravity of a forklift make it fundamentally different from transporting standard freight. A single mistake—whether in planning, loading, or securing—can lead to catastrophic consequences, including severe injury, property damage, and costly fines. This article serves as a comprehensive technical guide, meticulously detailing each step of the process to ensure a safe, efficient, and compliant transport operation. We will explore the critical planning and preparation stages, the meticulous loading and securing procedures, and the final, often overlooked, steps of transport and unloading.

Phase 1: The Planning and Assessment Phase - The Foundation of a Safe Transport

The most critical phase of any transport operation occurs before a single wheel turns. Proper planning minimizes risk and ensures all regulatory and safety requirements are met. This phase is about gathering information and making informed decisions.

1.1 Pre-Transport Assessment of the Forklift

Before anything else, you must have a complete understanding of the forklift itself. This goes beyond knowing its make and model.

Weight and Dimensions: Obtain the exact operating weight of the forklift, including any attachments like side-shifters, fork positioners, or specialized clamps. Also, measure its precise length, width, and height. Remember to account for the mast height when fully lowered, as this is the critical dimension for transport under bridges or through tunnels.

Center of Gravity: The center of gravity (CoG) of a forklift is not static. It shifts with the mast and forks, and its high position is a primary reason for instability during transport. Understanding its approximate location is crucial for proper loading and securing. For most forklifts, the CoG is low and centered when the forks are empty and fully lowered.

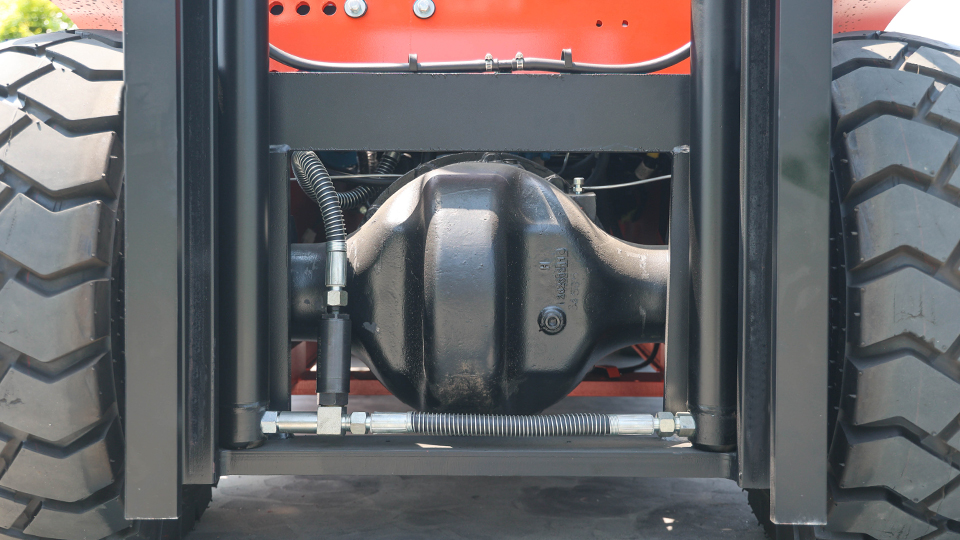

Forklift Type: Is it a counterbalanced internal combustion (IC) or electric forklift? Is it a rough-terrain telehandler or a compact warehouse model? The type dictates specific preparation steps, such as disconnecting batteries for electric models or securing fuel lines for IC engines.

Condition: Inspect the forklift for any leaks (hydraulic fluid, engine oil), damaged tires, or loose parts. Any pre-existing issues must be documented and addressed before transport.

1.2 Carrier and Trailer Selection

Choosing the right transport partner and equipment is paramount. Not all transport companies are equipped to handle heavy machinery, and not all trailers are suitable.

Specialized Carriers: Select a transport company with a proven track record of hauling heavy equipment, specifically forklifts. They should have experience with the unique challenges of their weight distribution and securing requirements.

Trailer Type: The most common trailer types for forklifts are:

Flatbed Trailer: A standard flatbed is often used for smaller, lighter forklifts. Its open design allows for easy loading and securing from all sides.

Step-Deck Trailer (or Drop Deck): With a lower rear deck, a step-deck trailer is ideal for taller forklifts, as it provides extra vertical clearance to avoid height restrictions on the road.

Lowboy Trailer (or Double Drop): For extremely heavy or tall forklifts and other heavy machinery, a lowboy trailer is the safest option. Its deck sits very low to the ground, offering maximum clearance and stability.

1.3 Permitting and Legal Requirements

Ignoring legal requirements can lead to severe fines, delays, or the impoundment of the cargo.

Weight, Height, and Width Regulations: Each state and country has specific regulations regarding the maximum legal weight, height, and width of a loaded vehicle. If your forklift exceeds these limits, you will need to obtain special permits.

Route Planning: The carrier must meticulously plan the route to avoid bridges, overpasses, and tunnels that cannot accommodate the loaded height and weight. This is a primary reason why specialized carriers with route-planning expertise are essential.

Phase 2: Preparation and Documentation - Readying the Forklift for the Journey

Once the planning is complete, the physical preparation of the forklift begins. This phase is all about making the machine safe for transport and ensuring a smooth loading process.

2.1 Preparing the Forklift

Cleanliness and Inspection: Before loading, the forklift should be cleaned to remove mud, oil, or debris that could affect traction during loading or cause securing issues. A final, thorough inspection for leaks or damage is also required.

Securing Components:

Forks and Mast: The mast should be fully lowered and tilted forward. The forks should be centered and lowered to a height that allows them to rest on the deck of the trailer or a designated support.

Attachments: Any loose attachments, such as fork extensions, should be removed and secured separately.

Steering: The steering wheel should be secured with a steering wheel lock to prevent it from turning during transport.

Power Disconnection:

Electric Forklifts: Disconnect the battery. This prevents accidental power surges and ensures the forklift cannot be started during transport.

Internal Combustion Forklifts: Turn off the engine and secure the fuel cap. If possible, consider shutting off the fuel line to prevent leaks.

Braking: Engage the parking brake to prevent the forklift from rolling.

2.2 Documentation

Proper documentation is a non-negotiable part of the process. This includes:

Bill of Lading (BOL): A legal document that details the type, quantity, and destination of the goods being transported. It should include the forklift’s dimensions, weight, and any special instructions.

Inspection Report: A document detailing the forklift’s condition before loading, including any pre-existing damage. This protects both the owner and the carrier.

Permits: All necessary permits for oversize or overweight transport must be readily available to the driver.

Phase 3: The Loading Process - The Moment of Truth

Loading the forklift is a high-risk activity that demands extreme care, clear communication, and adherence to a strict protocol.

3.1 Site Preparation

The loading site must be level, firm, and free of debris. Unstable ground can cause the trailer to shift or the ramps to slip, leading to an accident. The driver and forklift operator must agree on a clear loading plan.

3.2 Loading with Ramps

Ramp Inspection: Inspect the ramps for damage and ensure they are properly secured to the trailer. The angle of the ramps should be as shallow as possible to prevent the forklift from tipping backward.

The Spotter: A spotter is essential. They should be in a position to see both the forklift operator and the trailer, providing clear, concise instructions.

Driving Up the Ramps: The forklift operator must approach the ramps slowly and deliberately. The weight distribution of a forklift is unique; the heaviest part is the rear counterweight. For this reason, the forklift should be driven up the ramps in reverse to keep the heaviest part of the machine on the high side of the incline. This prevents the CoG from shifting dangerously and causing a tip-over. .

Positioning on the Trailer: Once on the trailer, the forklift must be positioned centrally and as far forward as possible to balance the load and distribute the weight evenly over the trailer axles. The mast should be fully lowered and the forks rested on the deck.

3.3 Loading with a Loading Dock

If a loading dock is used, the process is less inclined but still requires careful execution. The forklift operator drives onto the trailer directly from the dock. The same principles of slow, deliberate movement and central positioning apply.

Phase 4: Securing the Load - The Most Critical Task

Properly securing the forklift is the single most important step to ensure a safe journey. This process is not just about keeping the forklift on the trailer; it's about preventing it from shifting, sliding, or bouncing, which could cause it to break free.

4.1 Understanding Forces

The forklift must be secured against all four directions of force:

Forward: When the truck brakes suddenly.

Backward: When the truck accelerates quickly.

Side-to-Side: When the truck turns a corner.

Vertical Bounce: When the truck hits a bump or pothole.

4.2 Tie-Down Points

Use Designated Points: Always use the manufacturer-designated tie-down points on the forklift's frame. These are reinforced to handle the immense stress of securing a heavy machine.

Chains and Binders: Chains and binders are the industry standard for securing heavy equipment. They are stronger and more reliable than straps. Always use chains and binders with a working load limit (WLL) that exceeds the weight of the forklift.

4.3 The 4-Point Tie-Down Method

The 4-point method is the minimum required for securing a forklift.

The Process:

Attach two chains to the front of the forklift's frame, one on each side. These chains should be pulled forward and outward, creating a "V" shape. Secure them to anchor points on the trailer.

Attach two chains to the rear of the forklift's frame, one on each side. These chains should be pulled backward and outward, also creating a "V" shape. Secure them to anchor points on the trailer.

Engage the binders to tighten all four chains. Ensure they are taut but not over-tightened, which could damage the forklift or the trailer.

The chains should be placed at an angle of roughly 45 degrees to provide both horizontal and vertical resistance. .

4.4 Additional Securing Measures

Wheel Chocks: Placing wheel chocks in front of and behind the forklift's tires provides an additional layer of security against forward and backward movement.

Dunnage or Blocks: Placing wooden blocks or dunnage between the forklift's frame and the trailer deck can prevent slipping and distribute pressure.

Phase 5: Transport and Unloading

The journey is not over until the forklift is safely on the ground at its destination.

5.1 En Route Inspections

The driver has a responsibility to perform regular checks on the load, especially during the first few miles of the journey. This ensures that the chains have not loosened and that the load remains stable.

5.2 The Unloading Process

Site Assessment: Just like with loading, the unloading site must be level, firm, and safe.

Reverse the Process: Unloading is a reversal of the loading procedure. The driver should park the trailer on level ground and a spotter should be present.

Release Tie-Downs: All chains and binders must be removed before the forklift is moved. Attempting to drive the forklift while it is still secured is extremely dangerous and can cause severe damage.

Drive Off the Ramps: The forklift should be driven off the ramps slowly and carefully. The operator must be aware of the change in weight distribution as the machine descends the incline.

Conclusion

Transporting a forklift is a task that demands careful planning, meticulous execution, and unwavering attention to safety. From the initial assessment and carrier selection to the final, deliberate unloading, every step is a critical link in the chain of a successful operation. By understanding the unique characteristics of a forklift and adhering to the protocols outlined in this guide—including proper documentation, the use of a spotter, and the robust 4-point tie-down method—you can mitigate risks and ensure that this powerful piece of machinery arrives at its destination safely and securely. While this guide provides a technical framework, the ultimate success of the transport relies on the expertise of trained professionals who respect the inherent dangers and complexities of the task. For most organizations, partnering with a specialized heavy equipment transport company remains the safest and most reliable solution.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China