I. Introduction: The Criticality of the Capacity Rating

In the high-stakes environment of material handling, operating a powered industrial truck (PIT), commonly known as a forklift, is an act of applied physics. The single most critical piece of information an operator must know before engaging a load is the maximum weight the machine can safely lift under specific conditions.1 This is the rated capacity, and it forms the bedrock of safe operation and regulatory compliance.2

Under the Occupational Safety and Health Administration (OSHA) standard 29 CFR 1910.178(a)(6), the legal requirement is explicit: “The user shall see that all nameplates and markings are in place and are maintained in a legible condition.” This is not a suggestion; it is a mandate.3

The answer to the question, "Where can the capacity of the forklift readily be found?" is singular and non-negotiable: The Data Plate.

This technical article will dissect the forklift Data Plate (or Nameplate/Capacity Plate), explaining its required location, the critical capacity information it presents, and the core physical principles—namely the Load Center—that determine its ever-changing limits.

II. Locating the Data Plate: The Mandatory Placard

The Data Plate is the permanent, metal or plastic placard that serves as the official operational passport for the machine.4 It is the primary source of all operational specifications and is required to be easily accessible and legible to the operator.5

A. Standard Location Requirements

OSHA and industry standards (such as ANSI/ITSDF B56.1) dictate that this plate must be prominently displayed and maintained.6

Primary Location: The data plate is typically found inside the operator’s compartment, affixed to the instrument panel (cowl), the dashboard, or near the hydraulic controls.7 The goal is to place it where the operator can readily check it before and during operation without excessive effort or distraction.8

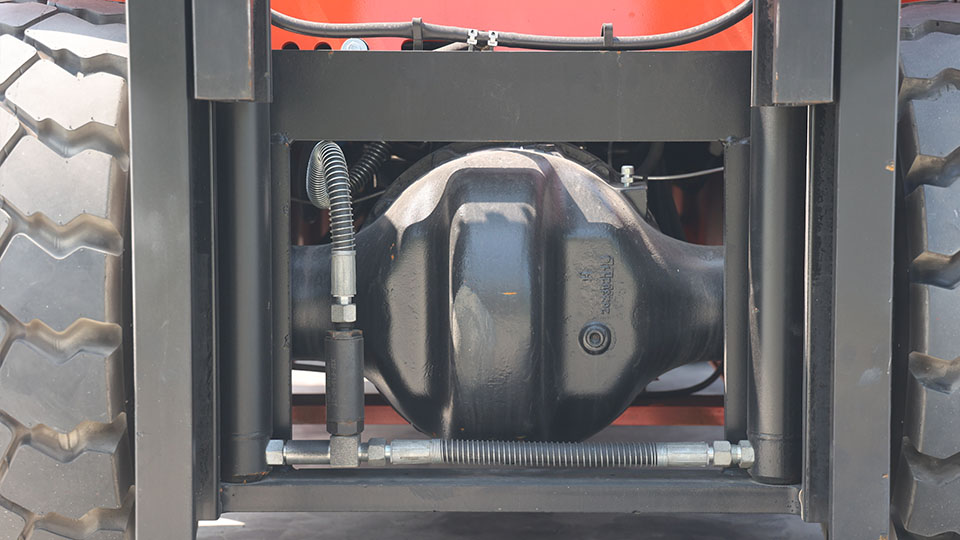

Alternative Locations: On some truck classes (like certain stand-up riders or rough terrain forklifts), it may be on the protective overhead guard frame or on the engine hood adjacent to the operator's seat.9

Legal Necessity: A forklift missing a legible data plate is not compliant with federal regulations and must be immediately removed from service until a replacement plate with the correct, engineering-approved specifications is secured from the manufacturer or a qualified engineering firm.10 Operating a PIT without a readable data plate is one of the most common and easily avoidable OSHA citations.11

B. The Unchanging vs. The Dynamic Rating

It is critical to understand that the capacity listed on the plate is the manufacturer’s initial, rated capacity—the maximum weight the truck can lift under ideal conditions. However, this figure is often a starting point, not a static limit.

The plate may show the factory-rated capacity (e.g., 5,000 lbs).12

It must then show the current, de-rated capacity if any modifications (like attachments) or non-standard configurations are in place.13 This makes the data plate a dynamic document reflecting the truck's current, safe operational limits.

III. Decoding the Data Plate: Beyond the Max Capacity Number

The capacity rating on the plate is inextricably linked to two other key variables, all of which are displayed visually and numerically on the data plate's capacity chart section.

A. The Rated Capacity

This is the largest weight the truck is designed to lift.14 It is almost universally listed in both pounds (lbs) and kilograms (kg).15

The Caveat: This number is only valid when the load meets the specific Load Center and Maximum Lift Height criteria also listed on the plate.16 Operators who only memorize the max weight without understanding the variables are a safety liability.17

B. The Load Center (LC)

The Load Center is the most important concept in forklift stability and is mathematically tied to the capacity rating. The load center is the measurement from the vertical face of the forks to the center of gravity of the load.18

Horizontal Load Center (HLC): The distance measured horizontally from the fork face to the load's center of gravity.19

Vertical Load Center (VLC): The distance measured vertically from the top surface of the forks (the blades) to the load's center of gravity.20

The Standard Assumption: Most forklifts under 30,000 lbs capacity in North America are rated with a standard 24-inch HLC (e.g., capable of handling a uniform 48-inch long pallet).21 Larger trucks may use a 36-inch or 48-inch HLC.22

Physics of Leverage: The further the load center moves away from the vertical face of the forks (i.e., the longer the load), the greater the leverage it applies against the truck's stability. This increased leverage decreases the rated lifting capacity.23 A load that extends past the rated load center may drop the maximum safe lift capacity by hundreds or even thousands of pounds.24

C. The Maximum Lift Height

The data plate will display the rated capacity at the maximum safe fork height for the specific mast configuration.25

Stability Triangle: The stability of the forklift operates on a "Stability Triangle" . As the load is raised, the combined center of gravity for the truck and the load also rises. The higher the center of gravity, the smaller the margin for error and the greater the risk of a lateral or longitudinal tip-over.

The Capacity Chart: Often, the plate will feature a chart or table showing de-rated capacities at different lift heights (e.g., 5,000 lbs at 100" and 4,200 lbs at 189" max height). This visually reinforces the principle that height reduces capacity.

IV. The Impact of Attachments and Modifications

One of the most frequent causes of capacity-related accidents stems from the installation of non-standard forks or attachments. The Data Plate must be immediately updated whenever a modification affects the truck's stability or capacity.

A. The De-Rating Requirement

Any attachment (e.g., side shifters, fork positioners, roll clamps, drum grabbers) changes the load center by adding weight forward of the main lift mechanism. This change always reduces the rated capacity of the forklift.

The New Data Plate: OSHA regulation 1910.178(a)(4) requires that modifications affecting capacity must not be performed without the manufacturer's written approval, and that capacity plates and tags shall be changed accordingly.26

Attachment Information: The updated data plate must not only reflect the new, lower maximum capacity but also identify the specific attachment that caused the change.27 An operator encountering an unfamiliar attachment must always check the plate to ensure they are using the new, correct maximum capacity.28

B. The Battery Weight Factor (Electric Trucks)

For electric-powered forklifts (Classes I and II), the battery acts as a significant part of the required counterbalance.

Essential Data: The data plate will specify the minimum and maximum required battery weight.29 Using a battery lighter than the minimum required weight will dangerously reduce the truck’s counterbalancing ability and invalidate the rated capacity on the plate, making the truck highly susceptible to forward tip-over.30

V. Operator Responsibility: The Technical and Ethical Mandate

The data plate is not a technical detail for engineers; it is the operator's primary safety tool.31 An operator is legally and ethically obligated to consult and understand the data plate every time they intend to lift a non-standard load or a load approaching the truck's limit.

|

Operator Action Checklist |

Reference Point on Data Plate |

Physics Principle |

|

Pre-Shift Inspection |

Check that the data plate is present, legible, and not damaged. |

Regulatory Compliance (1910.178(a)(6)) |

|

Load Assessment |

Locate the rated capacity, load center, and max height. |

Stability & Overturning Moment |

|

Non-Standard Load |

Use the Load Center diagram/chart to de-rate the capacity for non-standard loads (e.g., long coils). |

Leverage Principle: Capacity decreases as HLC increases. |

|

High Stacking |

Reference the capacity at maximum lift height on the chart. |

Center of Gravity Rises: Stability margin is reduced. |

|

Attachment Use |

Confirm the plate reflects the attachment, and use the de-rated capacity. |

Combined Weight and Forward Leverage |

The ability to "readily find" the capacity is therefore two-fold: physically locating the plate (the technical requirement) and accurately interpreting the capacity chart (the operator's responsibility). A professional operator understands that the Data Plate is the constant reminder that safety is a calculation, not an assumption.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China