I. Understanding the Forklift Braking Architecture

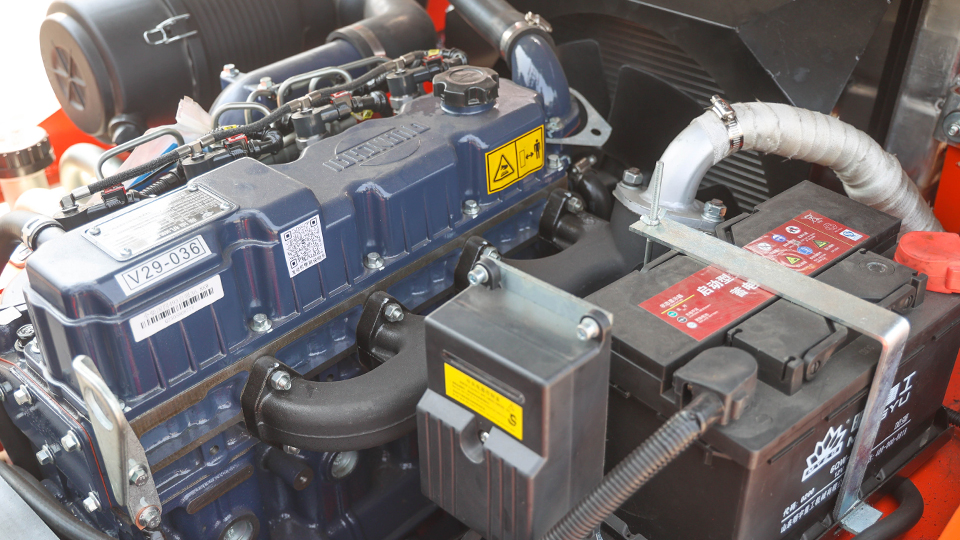

Unlike passenger vehicles, forklifts often use specialized braking configurations designed for "inch-and-brake" maneuvers. Most industrial forklifts utilize one of two systems:

Drum Brakes: Common in internal combustion (IC) forklifts, where brake shoes press against the inner surface of a rotating drum.1

Wet Disc Brakes: Common in high-end electric and heavy-duty IC models. These are enclosed in the axle and cooled by oil, offering superior longevity in dusty environments.2

II. Brake Pad and Shoe Wear Detection

The friction material on brake pads (or shoes) is a consumable.3 If allowed to wear down to the metal backing plate, it will cause "metal-on-metal" contact, destroying the drums or rotors and significantly increasing stopping distances.

1. Indicators of Excessive Wear

Increased Pedal Travel: If the operator has to push the pedal nearly to the floorboard to engage the brakes, the gap between the friction material and the drum has likely become too wide.

The "Squeal" or "Grind": High-pitched noises often indicate that the wear indicator (a small metal tab) is touching the rotor. A grinding sound suggests the friction material is completely gone.4

Brake Pull: If the forklift "pulls" to one side during braking, it indicates uneven wear or a stuck caliper/slave cylinder on one side.5

2. Technical Inspection Procedure

Thickness Measurement: For drum brakes, the lining should typically be replaced if it is less than 1.5mm to 2mm thick.

Glazing Inspection: High-heat environments can "glaze" the pads, creating a mirror-like finish that lacks the necessary friction coefficient.6 Glazed pads must be deglazed with sandpaper or replaced.

Heat Cracking: Inspect the shoes for "spiderweb" cracks, which indicate the material has been subjected to temperatures beyond its design limit.

III. Brake Fluid: The Hydraulic Lifeline

Brake fluid is hygroscopic, meaning it actively absorbs moisture from the atmosphere.7 In a humid warehouse or outdoor yard, this moisture absorption is accelerated.

1. The Danger of Moisture Contamination

As moisture content increases, the boiling point of the brake fluid decreases.8 During heavy use, the heat from the brakes can cause the water in the fluid to boil, turning it into steam. Unlike liquid, steam is compressible, leading to a "spongy" pedal and total brake failure (vapor lock).9

2. Replacement Cycles and Standards

The Standard Cycle: For most industrial forklifts, brake fluid should be flushed and replaced every 12 months or 2,000 operating hours.10

DOT Grade Integrity: Most forklifts require DOT 3 or DOT 4 fluid. However, never mix the two unless specified, as their chemical compositions and boiling points differ.

Fluid Color Check: Fresh fluid is clear or slightly amber. If the fluid in the reservoir appears dark, cloudy, or "muddy," it is contaminated with moisture and rubber particles from degrading seals and must be flushed immediately.

IV. Fault Warning Signs and Troubleshooting

Modern forklifts, particularly electric models, feature electronic monitoring, but mechanical warnings remain the primary line of defense.

|

Warning Sign |

Potential Fault |

Action Required |

|

Spongy Pedal |

Air or moisture in hydraulic lines |

Bleed the system and check for leaks. |

|

Brake Drag |

Weak return springs or stuck pistons |

Disassemble and lubricate moving parts. |

|

Low Fluid Light |

Leak in line or extremely worn pads |

Inspect wheel cylinders and hose junctions. |

|

Vibration11 |

Warped brake drums or rotors12 |

Resurface (turn) or replace the drums.13 |

The "Inching Pedal" Factor

On many forklifts, the left pedal acts as both a brake and a transmission disengagement tool (the inching valve).14 If the forklift brakes poorly only when using the left pedal, the fault lies in the inching valve linkage adjustment rather than the brake pads themselves.

V. Maintenance Strategy: Proactive vs. Reactive

To minimize downtime, maintenance should follow a tiered approach:

Daily (Operator): Check brake fluid levels and test brake responsiveness before starting the shift.

Monthly (Technician): Inspect hoses for leaks and check the tension of the parking brake cable.

Annually: Perform a full "wheels-off" inspection of the drums/discs and replace the fluid.

Conclusion

Forklift braking systems are robust but not invincible. The combination of heavy loads and stop-and-go duty cycles makes brake pad wear and fluid degradation inevitable. By adhering to a strict 2,000-hour fluid replacement cycle and performing monthly thickness checks on friction materials, facilities can prevent the most common causes of forklift accidents.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China