In the global industrial landscape of 2026, the demand for Aerial Work Platforms (AWPs) has transcended traditional construction boundaries. From the maintenance of solar farms in the Australian outback to the dense urban redevelopment projects in Berlin and Tokyo, one specific category of machinery has emerged as the "global bestseller."

What separates a standard lift from a high-demand export powerhouse? The answer lies in the intersection of international safety compliance, modular engineering, and universal serviceability. This article explores the technical architecture of the world's most successful export-grade AWPs and why they have become the "universal language" of high-altitude work.

1. The Foundation of Export Success: Global Safety Compliance

For a piece of heavy machinery to be "sold all over the world," it must navigate a complex web of regional regulations. The best-selling platforms are engineered to meet or exceed three primary global standards simultaneously:

ANSI/SAIA A92 (United States): Focuses heavily on stability testing, load sensing, and operator training requirements.

CE / EN280 (European Union): Known for the most stringent requirements regarding tilt sensors, emergency lowering systems, and structural integrity.

AS/NZS 1418.10 (Australia/New Zealand): Often requires specific modifications for "rough terrain" performance and unique electrical insulation standards.

By designing a "Global Chassis," manufacturers ensure that a machine built in one region can be shipped and operated in another without costly retrofitting. This compliance is managed through an integrated Safety Control Unit (SCU) that can be toggled via software to match the specific safety parameters of the destination country.

2. Technical Features of the Global Bestseller

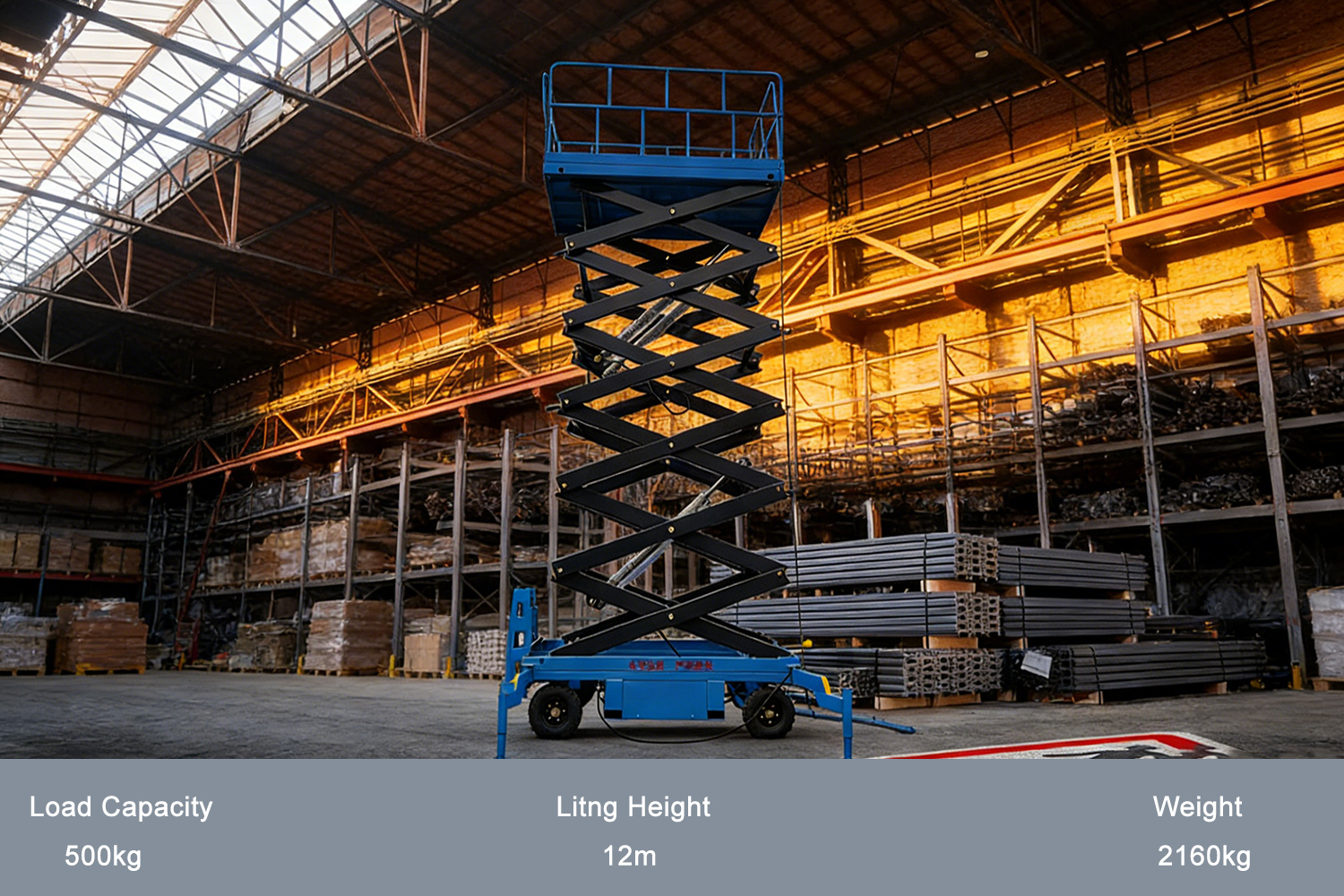

To achieve high-volume foreign trade success, a platform must be more than just safe; it must be technologically superior. The leading export models—typically electric scissor lifts and telescopic boom lifts—share several core technical traits.

A. Intelligent Load-Sensing Systems

Gone are the days of simple pressure switches. The top-selling international units utilize strain-gauge transducers integrated into the platform support. These sensors provide real-time data to the machine's CPU. If the platform is overloaded, the system doesn't just buzz; it locks out all hazardous functions while allowing the operator to lower the basket safely. This prevents the "over-reaching" accidents common in emerging markets.

B. High-Performance Lithium-Ion Powertrains

In 2026, the global market has pivoted away from lead-acid batteries. The best-selling export units are powered by LiFePO4 (Lithium Iron Phosphate) battery packs.

Universal Charging: Onboard chargers are designed to accept voltages ranging from 110V to 240V and frequencies of 50Hz to 60Hz, allowing the machine to be plugged in anywhere in the world.

Zero Emissions: This enables the same machine to work indoors in a pharmaceutical plant in Switzerland or outdoors on a jobsite in Brazil.

C. Advanced Telematics and Remote Diagnostics

A machine sold thousands of miles from the factory must be easy to fix. High-export AWPs are equipped with 5G-enabled telematics.

Remote Troubleshooting: A technician in the home office can dial into a machine in Dubai to diagnose a hydraulic valve failure.

GPS Geo-fencing: International rental companies use this to track assets across borders and ensure machines aren't operated in unauthorized, dangerous zones.

3. Engineering for Extreme Environments

To be a "global" bestseller, the machine must survive the humidity of Southeast Asia, the dry heat of the Middle East, and the freezing winters of Northern Canada.

|

Component |

Technical Adaptation for Global Export |

|

Hydraulic Systems |

Multi-grade bio-oils that maintain viscosity at $-20°C$ to $+50°C$. |

|

Electrical Connectors |

IP67-rated sealed harnesses to prevent corrosion from salt air in coastal regions. |

|

Finish/Coating |

Electrophoretic deposition (E-coat) painting for 10-year rust protection. |

|

User Interface |

Multilingual LCD displays supporting 20+ languages for diverse workforces. |

4. The Logistics of Foreign Trade: Modular Design

One of the most overlooked technical aspects of the best-selling AWPs is their shipping-optimized design. Shipping costs can make or break an international deal.

The most successful manufacturers design their machines with:

Collapsible Guardrails: Reducing the machine's height so that multiple units can be double-stacked in a standard 40-foot "High Cube" shipping container.

Forklift Pockets and Tie-down Points: Standardized for international maritime transport, ensuring the machine arrives at the destination without structural stress from improper lashing.

5. Why "Globalized" AWPs are Safer

When a machine is built to the highest common denominator of international standards, safety improves for everyone. Even in regions where local regulations are lax, the presence of a "Global Bestseller" introduces:

Automatic Tilt Protection: The machine automatically limits its lift height if the ground slope exceeds $3°$.

Emergency Descent Redundancy: Multiple ways to lower the platform (manual bleed valves, electric auxiliary power, and gravity-lowering) ensure operators are never stranded at height.

Anti-Entrapment Bars: Standardized mechanical or ultrasonic "pressure bars" that stop the machine if the operator is pushed toward the control panel.

6. Conclusion: The Future of High-Altitude Export

The "Best-Selling" aerial work platform of today is a masterpiece of international cooperation. It represents a fusion of American stability, European safety logic, and Asian manufacturing efficiency. By complying with global standards and embracing the "Intelligence" of the 2026 technological era—IoT, Lithium power, and autonomous safety—these machines have become more than just tools; they are the safest way for the world to reach new heights.

As foreign trade continues to expand, the focus is shifting from "how high can it go?" to "how smart and safe can it be?" The machines that answer that question are the ones currently being shipped to every corner of the globe.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China