1. The Foundation: Daily Pre-Shift Inspections

Before diving into monthly or annual plans, maintenance begins with the Daily Operator Check. OSHA requires these inspections to ensure immediate safety.

Fluid Levels: Check hydraulic oil, engine oil, and coolant (for ICE trucks).

Tires: Look for "chunking," flat spots, or embedded debris.

Forks and Chains: Inspect for cracks, bends, or uneven wear.

Safety Devices: Test the horn, backup alarms, and lights.

2. Monthly Maintenance (Every 200–250 Hours)

Monthly maintenance is the first "deep dive" into the machine's mechanical health. This stage focuses on lubrication and cleaning to prevent friction-related failure.

Chassis and Moving Parts

The primary goal of the monthly service is lubrication. Forklifts have numerous grease points that dry out due to dust and heavy loads.

Greasing: Apply high-quality grease to the mast tracks, lift chains, and steering linkages.

Mast Operation: Inspect the lift and tilt cylinders for leaks. Ensure the mast moves smoothly without "chattering."

Internal Combustion (IC) Specifics

If you are running LPG, Diesel, or Gasoline trucks:

Air Filters: Clean or replace the air filter. Dust ingestion is a leading cause of engine failure.

Oil Change: Depending on the environment (e.g., a dusty brickyard vs. a clean pharma warehouse), the engine oil and filter should be replaced.

Electric Forklift Specifics

Battery Watering: For lead-acid batteries, check electrolyte levels and top off with distilled water after charging.

Cables: Inspect for fraying or "sulfation" (white crunchy buildup) on terminals.

3. Quarterly Maintenance (Every 500–600 Hours)

Quarterly maintenance shifts focus from "grease and oil" to systemic calibration and safety testing.

The Hydraulic System

The hydraulics are the "muscles" of the forklift.

Filter Replacement: Change the hydraulic return filter. Contaminants in the oil can score cylinder walls.

Pressure Testing: Use a pressure gauge to ensure the pump is producing the manufacturer-specified PSI.

Hose Inspection: Check for "weeping" at the crimps. A high-pressure hydraulic pinhole leak can be fatal if it contacts human skin.

Braking and Steering

Brake Pedal Travel: Measure the "free play" in the brake pedal. Adjust the shoes or pads if necessary.

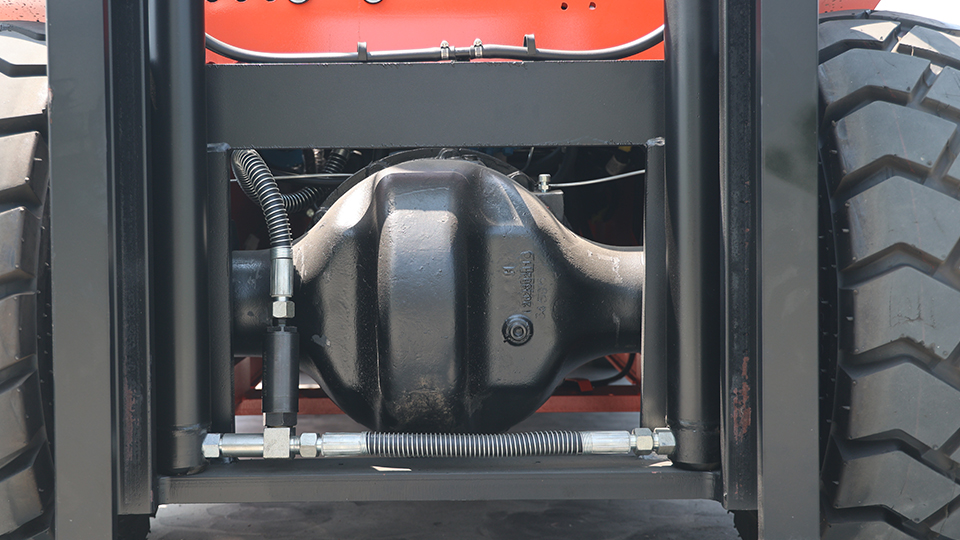

Steering Axle: Inspect the "kingpins" and steering bushings. Excessive "slop" in the steering wheel indicates worn-out bushings that can lead to accidents in tight aisles.

Drive Train (IC Models)

Drive Belt Tension: Check the alternator and fan belts for cracks or glazing.

Cooling System: Inspect the radiator fins for clogs. Use compressed air to blow out debris that can cause overheating.

4. Semi-Annual & Annual Maintenance (Every 1,000–2,000 Hours)

The annual inspection is often considered the "Grand Service." This is where you perform preventive replacements of major components before they fail.

Fluid Overhaul

At the 2,000-hour mark, most manufacturers recommend a total fluid flush:

Hydraulic Fluid Change: Old oil loses its viscosity and heat-dissipation properties.

Transmission Fluid: Drain and replace transmission oil and clean the internal strainer.

Coolant Flush: Replace the antifreeze to prevent internal corrosion of the engine block.

Chain and Fork Thickness

Chains and forks are "wear items." Over time, the metal thins.

Chain Elongation: Use a chain gauge to measure "stretch." If the chain has stretched more than 2-3%, it must be replaced immediately.

Fork Caliper Test: Measure the thickness of the fork blade. If the heel of the fork has worn down by 10% or more, its load capacity is reduced by 20%, and it is legally "out of service."

Electrical System Diagnostics

For electric trucks, this involves a "Contactor" inspection. Check the tips of the contactors for pitting or welding. If they stick, the truck could continue moving even after the operator releases the accelerator.

5. Adjusting for Usage Frequency

A "one size fits all" calendar doesn't work for every warehouse. You must adjust your schedule based on your Operating Environment.

|

Environment Type |

Usage Hours |

Maintenance Strategy |

|

Clean Warehouse |

40 hrs/week |

Standard Monthly/Annual intervals. |

|

High-Cycle/Multi-Shift |

100+ hrs/week |

Accelerate intervals by 50%. Perform "Monthly" checks every 2 weeks. |

|

Corrosive (Cold Storage/Brine) |

Any |

Daily lubrication of chains; weekly wash-downs to prevent rust. |

|

High Dust (Lumber/Construction) |

Any |

Daily air filter checks; weekly radiator blow-outs. |

6. The Cost of Neglect vs. Proactive Planning

Maintenance is often viewed as a "cost center," but the data suggests otherwise.

Reactive Maintenance: Costs 3x–4x more than scheduled maintenance due to emergency repair fees and lost productivity.

Trade-in Value: A forklift with a documented service history (the "logbook") can command a 15-25% higher resale value.

Digital Record Keeping

Moving away from paper logs to a CMMS (Computerized Maintenance Management System) allows fleet managers to track "Cost Per Hour." If a specific truck's maintenance cost begins to climb steeply, it acts as a signal that the machine has reached its "economic end of life" and should be replaced.

Conclusion: A Culture of Maintenance

A successful forklift maintenance plan isn't just about the mechanics; it's about the operators. When operators know that their feedback on a "squeaky brake" will be addressed during the next monthly service, they are more likely to take pride in the equipment.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China