The dual brake pedal system on certain Doosan forklifts is designed to enhance operator control, safety, and productivity. It typically consists of a clutch brake pedal and a service brake pedal. Each pedal serves a distinct, yet interconnected, function.

Clutch Brake Pedal

The clutch brake pedal, often the left pedal, disengages the transmission from the engine and applies the brakes simultaneously. This allows the operator to stop the forklift and shift gears without stalling the engine. The primary purpose of this pedal is to provide a smooth, controlled stop and enable precise maneuvering, especially in tight spaces or when inching forward to pick up or set down a load.

Service Brake Pedal

The service brake pedal, often the right pedal, operates as a standard brake. Its primary function is to apply the brakes to slow down or stop the forklift without disengaging the transmission. This is used for general braking during travel and when the operator needs to stop without the intention of changing gears.

Synergy and Operational Benefits

The combination of these two pedals provides a more nuanced control system for the operator. The clutch brake pedal is particularly useful in applications that require frequent starting and stopping, such as loading and unloading trailers or stacking goods in a warehouse. It reduces wear and tear on the transmission and clutch components by preventing the operator from "riding the clutch." The service brake pedal, on the other hand, is the go-to for standard braking operations.

Other Considerations

It's important to note that not all Doosan forklifts have this dual pedal system. The presence of two brake pedals is more common in internal combustion (IC) forklifts, particularly those with a powershift transmission. Electric forklifts and some newer models with hydrostatic transmissions often have a single brake pedal, as their drive systems operate differently and don't require a clutch function.

This dual-pedal design is a feature that distinguishes some Doosan models and contributes to their reputation for durability and performance in demanding work environments.

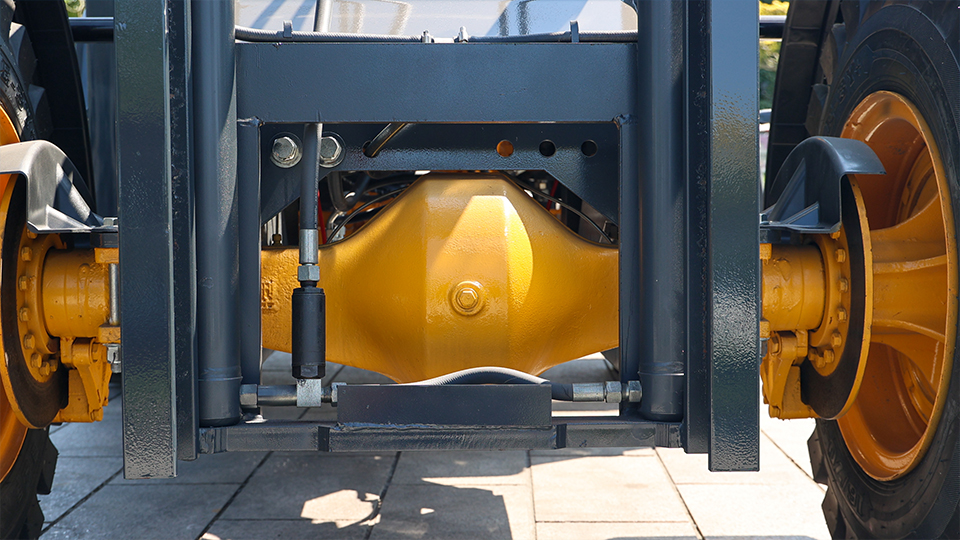

Some Doosan forklifts, particularly older internal combustion models, have two brake pedals to give the operator more precise control over the machine's movement and hydraulic functions. This dual-pedal system typically consists of an inching pedal (or clutch brake pedal) and a service brake pedal.

The Inching Pedal

The inching pedal is the left-most pedal and is used for fine-tuned maneuvering. It serves a dual purpose:

As you press it, it first disengages the transmission, similar to a clutch in a car. This allows the operator to rev the engine to increase the speed of the hydraulic functions (like lifting or tilting the mast) without causing the forklift to move. This is crucial for precise stacking or picking up heavy loads.

When the pedal is pressed down completely, it also activates the brakes, bringing the forklift to a stop.

The Service Brake Pedal

The service brake pedal is the right-most brake pedal and functions as a standard brake. It is used to slow down or stop the forklift without disengaging the transmission. This is the pedal you'd use for general braking during travel.

By having these two separate pedals, an operator can manage the forklift's travel speed and its hydraulic functions independently, which is a key benefit in applications that require frequent, precise movements, such as loading and unloading trucks or navigating narrow aisles.

Name: selena

Mobile:+86-13176910558

Tel:+86-0535-2090977

Whatsapp:8613181602336

Email:vip@mingyuforklift.com

Add:Xiaqiu Town, Laizhou, Yantai City, Shandong Province, China